Gas sensor not working reasons

There are many types of gas sensors and many reasons why they do not work. Here I will first analyze 4 types of Gas sensor not working reasons: electrochemical, non-dispersive infrared, ultraviolet ionization and catalytic combustion sensors.

Reasons for not working of electrochemical (EC) Gas sensor

- The active substance in the electrolyte is consumed. Depleted electrochemical sensors include lead oxygen sensors, water-based ammonia sensors, hydrogen fluoride sensors, and hydrogen cyanide sensors. As the active substance reacts with the gas being measured, the sensor slowly fails.

- The catalyst is covered with VOC. The catalyst for electrochemical sensors is a precious metal of tens to hundreds of nanometers. When electrochemical sensors are used in environments containing VOCs, the VOCs liquefy, cover the surface of the catalyst, and never leave the sensor again. Over time, the catalyst will not be able to contact the gas being measured, and the sensor will fail.

- Too much water evaporates from the electrolyte. Water-based electrochemical sensor carriers are hydrogen ions and hydroxide ions, when the water is less and less, the carriers will not be able to move freely between the working electrode and the counter electrode, the sensor will slowly fail.

- The sensor has mechanical damage. For example, the mechanical pressure caused by the sensor shell rupture, capillary compression, etc., will lead to permanent failure of the sensor.

Water droplets block the capillary pores. The top of the electrochemical sensor has a very small capillary hole, if there is liquid water will be the hole blocked, then the gas can not enter the sensor inside, the sensor will fail.

- Sensor catalyst poisoning. For example, if the HCN sensor is fed with H2S and PH3, the sensor catalyst will be poisoned and fail.

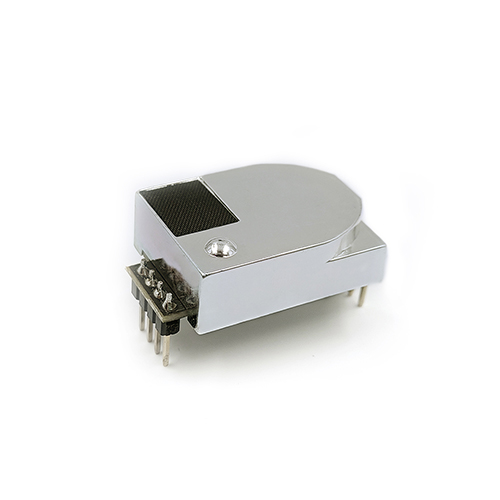

Non-dispersive infrared (NDIR) Gas sensor not working reason analysis

- There is condensation in the optical path. When there is liquid water in the optical path, the sensor reading will be very high, so you need to remove the liquid water, preferably condensation, when you normally intake air.

- There is dust or oil in the optical path. When there is dust or oil in the optical path, the sensor reading will also be very high, because these impervious substances absorb infrared light, resulting in inaccurate readings. To prevent this failure mode, oil and dust removal can be used. If the optical path is already contaminated, have the sensor manufacturer re-clean the optical path.

UV ionization (PID) sensor not working reason analysis

- UV lamp attenuation, UV light intensity is weakened, VOC is ionized by UV light, when the UV light intensity is weakened, the ionized VOC will of course become less, so the reading will become lower. Typically, a 10.6ev UV lamp has a life expectancy of 10,000 hours, while some suppliers may have UV lamps with a life expectancy of only 5,000 hours.

- Dust can cover the UV lamp and the fork finger electrode. When dust covers the UV lamp, the UV light intensity is reduced. When dust covers the fork-finger electrode, the electrode collects fewer positive or negative ions, so the reading will be lower.

- UV lamps do not light up. The inert gas inside the UV lamp needs an external alternating high voltage electric field to light up. If the inert gas inside the UV lamp is thin, or the high voltage is not enough, the UV lamp will not light up.

- Liquid water on the fork finger electrode. If there is high humidity in the environment and liquid water on the fork finger electrode, the electrode will short out, resulting in a very large sensor reading.

- High ambient humidity. Gaseous water also absorbs UV light. If the humidity of the gas being measured is very high, the sensor reading will be low by about 30% or so.

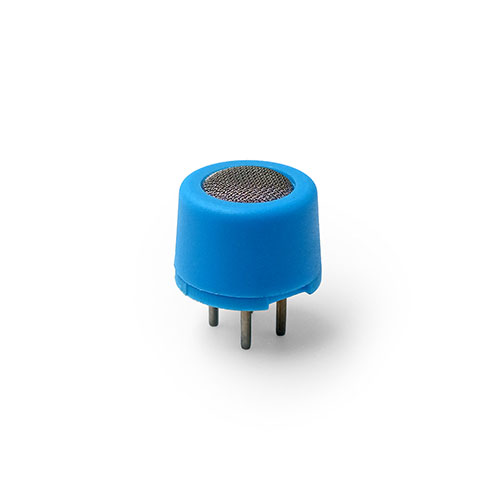

Catalytic combustion (CAT) sensor failure reason analysis

- No reaction in an oxygen-free environment. As we all know, CH4 combustion in the air requires the participation of oxygen, CH4 and O2 combustion ratio of 1: 2. The maximum O2 concentration in the air is 20.8%, that is to say, LEL sensors can be normal measurement of the concentration of CH4 in the range of 0% -10%. When the O2 is insufficient, the CH4 combustion on the LEL sensor element is not sufficient, and the temperature of the platinum wire can not rise to an accurate height, thus making the measurement inaccurate.

- catalyst poisoning. CAT sensor platinum wire and catalyst is exposed to the air, flammable and explosive gases and oxygen on the surface of the catalyst to react, so the catalyst has a failure problem (poisoning). According to experimental data, CAT sensor in 100ppm (ppm: parts per million) of H2S environment, as long as the time of 3 minutes, CAT sensor sensitivity will be reduced by 10%. CAT sensor not only H2S will be poisoned, but also on the organosilicon gas, chloride, bromide will be poisoned, so CAT sensor can not be in such an environment in the normal operation of a long period of time. In this “non-simple” environment, NDIR sensors are the ideal choice.

- Carbon buildup on the surface of the catalytic bead The definition of carbon buildup on CAT sensors is as follows: when a gas containing carbon (C) is incompletely burned on the catalytic bead, a small portion of the C atoms will attach to the sensor element, resulting in an inaccurate measurement of the gas.

- Platinum wire breakage. The CAT sensor uses a 10-20um diameter platinum wire inside the sensor, which is covered with a layer of catalyst and has a large mass, so the fragile link of the platinum wire is more prone to breakage when it is dropped on the ground.