Li-battery Thermal Runaway

Solution for Safety Monitoring of Power Batteries/Hydrogen Energy/Energy Storage Stations

The promotion of new energy is an important way to reduce greenhouse gas emissions and achieve the “dual carbon” target, and the safety issues that come with it have become a social concern. Based on a comprehensive gas sensor technology platform, Fosen Electronics provides a complete safety monitoring solution to ensure the safe development of the new energy industry.

Gas

Particulate matter

Pressure

Temperature

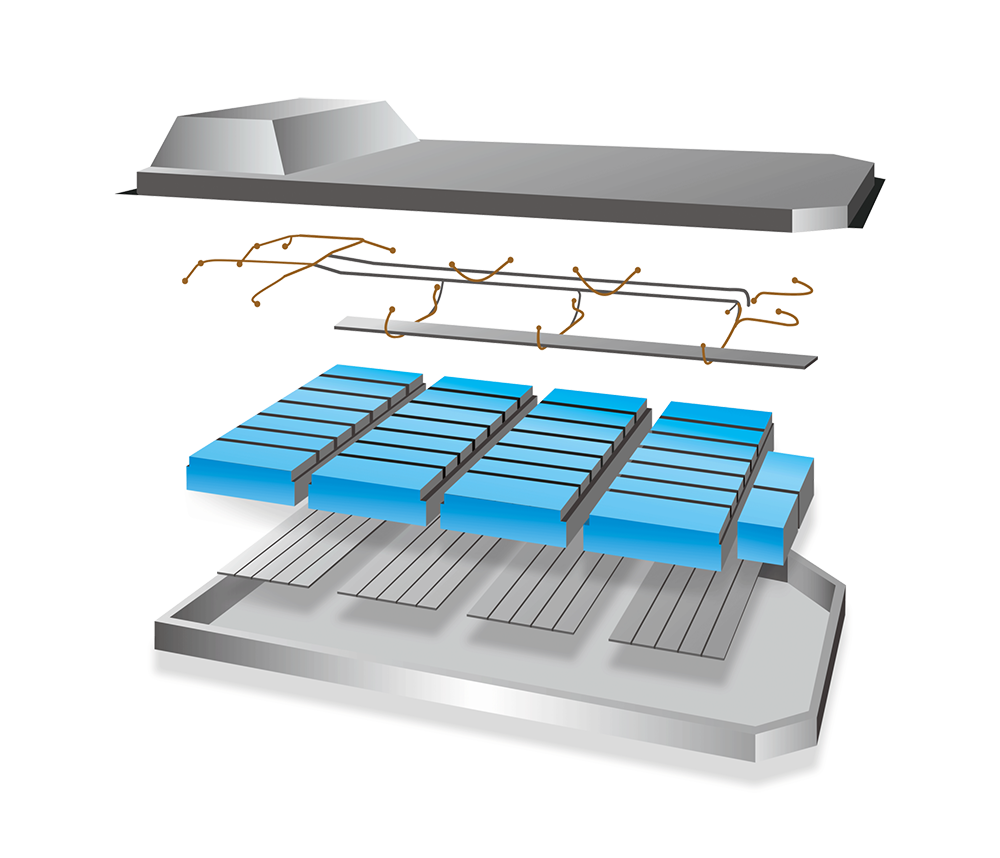

Fosen relies on its sophisticated gas sensor technology platform and creatively combines multiple technologies such as NDIR infrared, MEMS process MOx sensors, and laser light scattering to introduce an integrated thermal runaway warning sensor. This sensor can effectively monitor indicators such as CO2, CO, temperature, pressure, and aerosol particles released before the triggering of thermal runaway in lithium batteries, and sends signals through the CAN bus to the battery management system (BMS), playing a reliable role in thermal runaway warning.

Non-Dispersive Infrared (NDIR) technology is used to measure the concentration of CO2 by detecting the absorption of light at specific wavelengths as it passes through a sample gas. NDIR has several advantages including high accuracy, fast response time, and a long lifespan of up to 15 years.

MEMS sensors can measure CO with minimal impact from temperature and humidity, providing stable detection signals. They can also be extended to detect various gases. Furthermore, the lifespan of the handheld model of this sensor is over 15 years, and it has excellent corrosion resistance to organic silicon gas.

The laser scattering technology with independent intellectual property rights is used to measure PM (particulate matter) and enables accurate, fast, and real-time monitoring. In addition, it has a low power consumption mode.

The module adopts a mature circuit design that meets automotive industry standards and is capable of adapting to harsh in-vehicle environments.

Real-time communication. The protection level can reach IP65.

Hydrogen gas leak detection

FS02501 hydrogen sensor from Fujian Fusheng Electronic Technology is designed to detect hydrogen gas leaks in hydrogen fuel cell engines and hydrogen supply pipe systems, and sends real-time signals to hydrogen leak alarm devices. It can generate a general warning signal when detecting a minor hydrogen gas leak, while triggering a severe warning alarm and automatically shutting off the hydrogen supply in case of a major hydrogen gas leak.

Catalytic combustion gas sensing technology can measure H2 gas, and is not affected by factors such as acetic acid, siloxane, hydrogen sulfide, and vibration

The module adopts mature circuit design that meets the automotive industry’s standards and can adapt to harsh in-vehicle environments.

Real-time communication. The protection level can reach IP65.

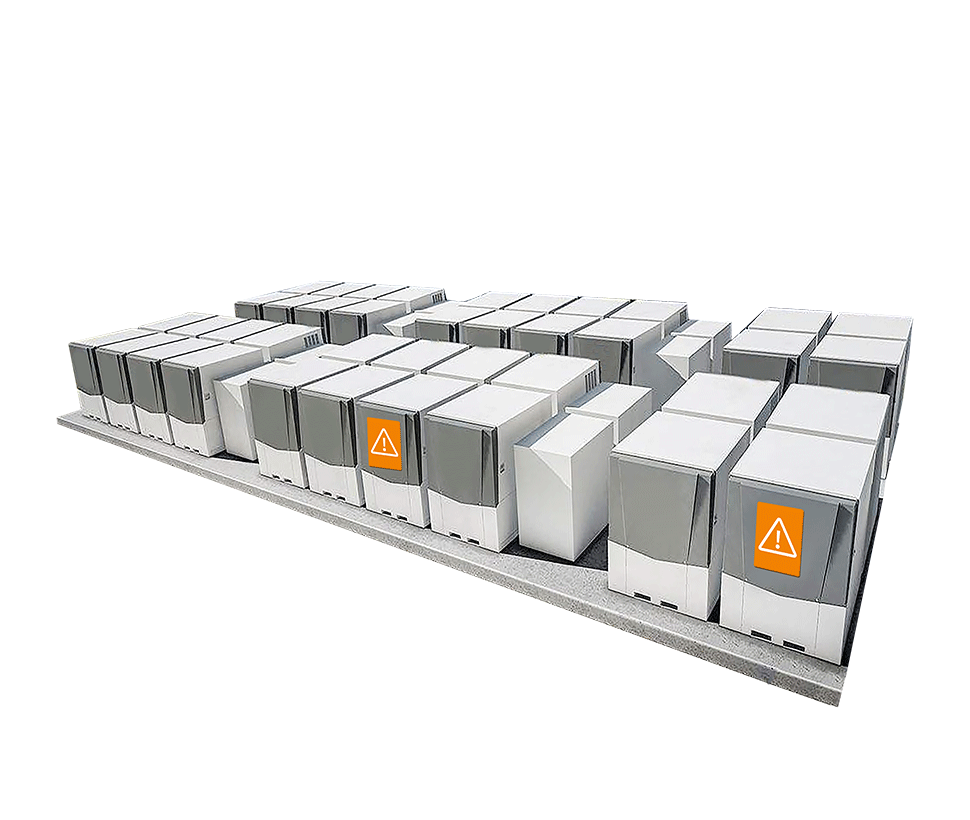

Thermal Runaway Alarm Detection for Energy Storage Station

Fosen has launched thermal runaway monitoring sensors and thermal runaway monitoring alarms based on its core gas sensor technology. These devices can monitor in real-time the gases, temperature, pressure, aerosol particles, etc., released before the occurrence of lithium battery thermal runaway, and provide early warning signals for abnormal conditions that may lead to thermal runaway in energy storage stations.

The mastery of key gas sensing technologies like non-dispersive infrared (NDIR), MEMS MOx, and laser scattering enables the realization of multi-sensor and multi-mode measurements.

Good gas selectivity, low temperature and humidity impact, stable detection signal.

The sensor has low power consumption, mature circuit design, good corrosion resistance, and a high protection rating of up to IP65, making it suitable for harsh working conditions.

A professional OEM/ODM team that possesses software, hardware, and structural design capabilities can provide customized solutions to customers. This team can independently develop the core components required for these solutions, thus providing a significant cost advantage.

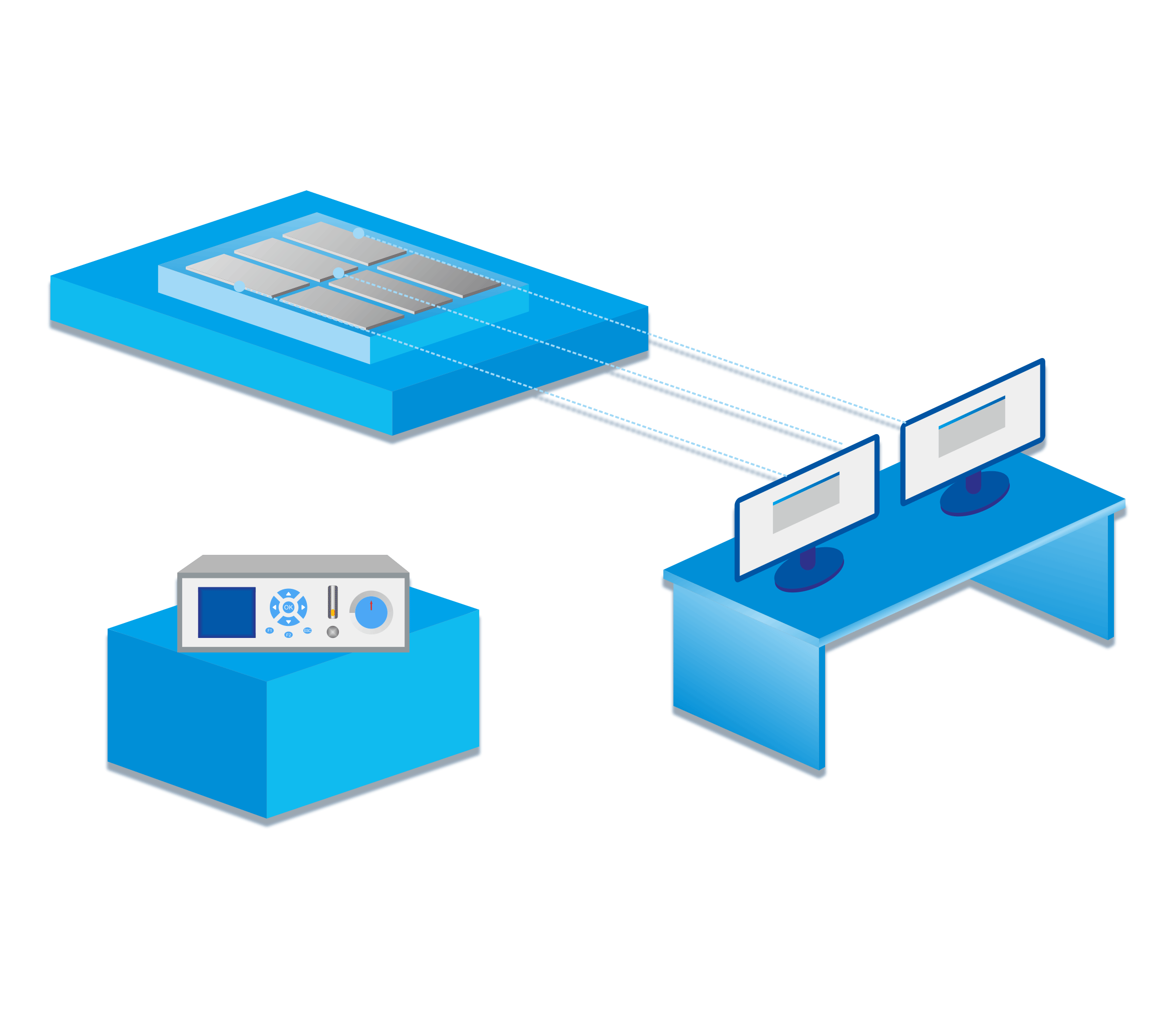

Research and Experimental Analysis of Battery Thermal Runaway Mechanism

Translation: Fosen Electronics adopts micro-flow infrared gas analysis technology to detect gases produced during the early stages of thermal runaway, providing fundamental research data for early warning of battery thermal runaway. Meanwhile, it utilizes a laser Raman spectrometer gas analyzer which was obtained through a national major scientific instrument project to measure the full composition of gases produced after thermal runaway occurs in real-time. Fosen Electronics can assist battery companies in quickly establishing testing facilities with both software and hardware components.

Efficient, fast, accurate, convenient, and reliable spectral analysis technology.

Indigenous micro-flow infrared half-sealed chamber gas sensing technology with independent intellectual property rights.

The fast response enables real-time online measurement, which can help battery companies quickly establish soft/hardware facilities for testing. Additionally, it can detect CH4.

The laser Raman spectroscopy gas analyzer 15S can complete the analysis and measurement of all gases, while the micro-flow infrared gas analyzer can simultaneously measure low concentrations of CO, CO2, and CH4 in the early stage of thermal runaway.