MEMS and nanotechnology for gas sensors

With the improvement of modern industry and living standard, the importance of air quality is increasing day by day. MEMS and nanotechnology, as an emerging detection technology for gas sensors, has a wider and wider range of applications, especially in the fields of environmental monitoring, industrial safety, healthcare and biology, which play an increasingly important role. In this paper, the basic principles, application scenarios, advantages and disadvantages as well as the future development direction of MEMS gas sensors will be elaborated and discussed.

The basic principle of MEMS technology for gas sensors

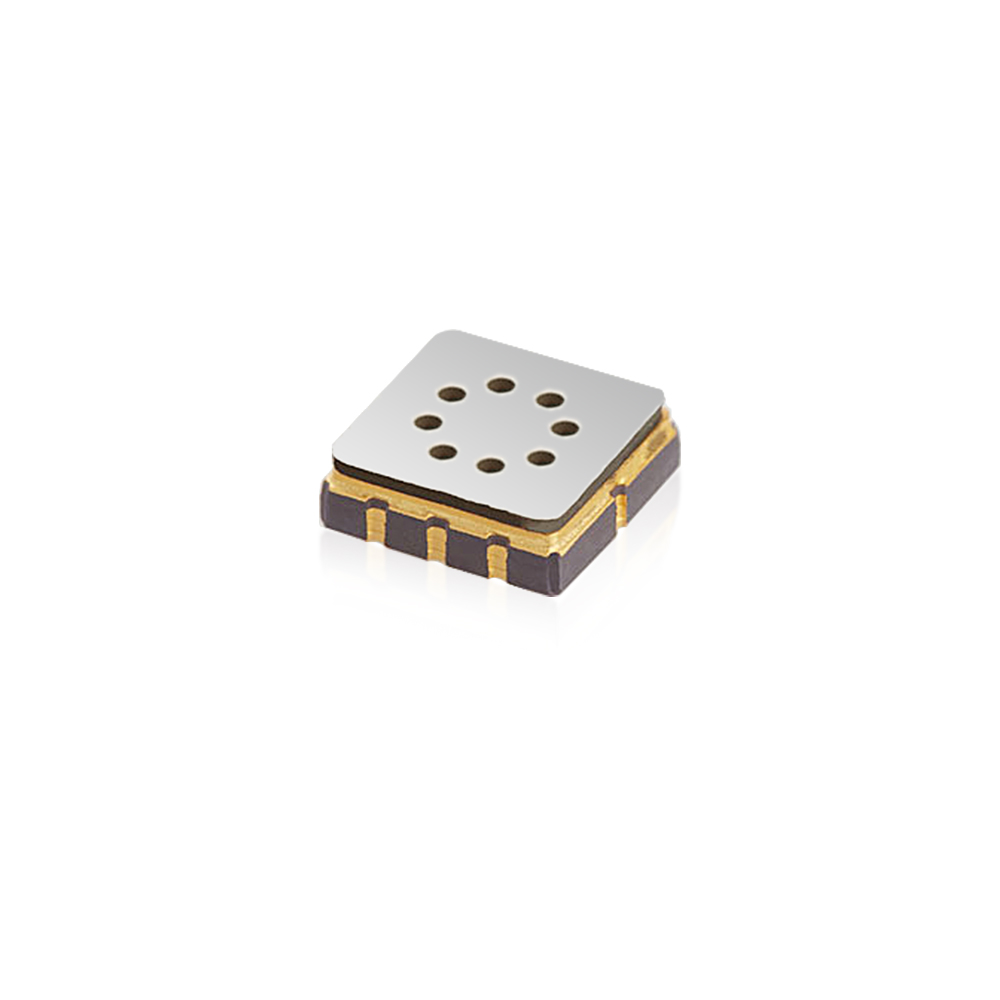

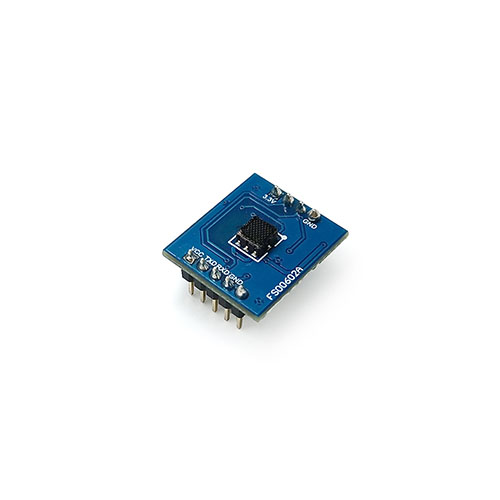

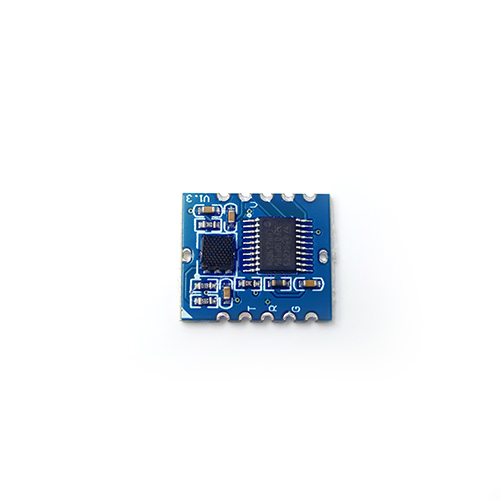

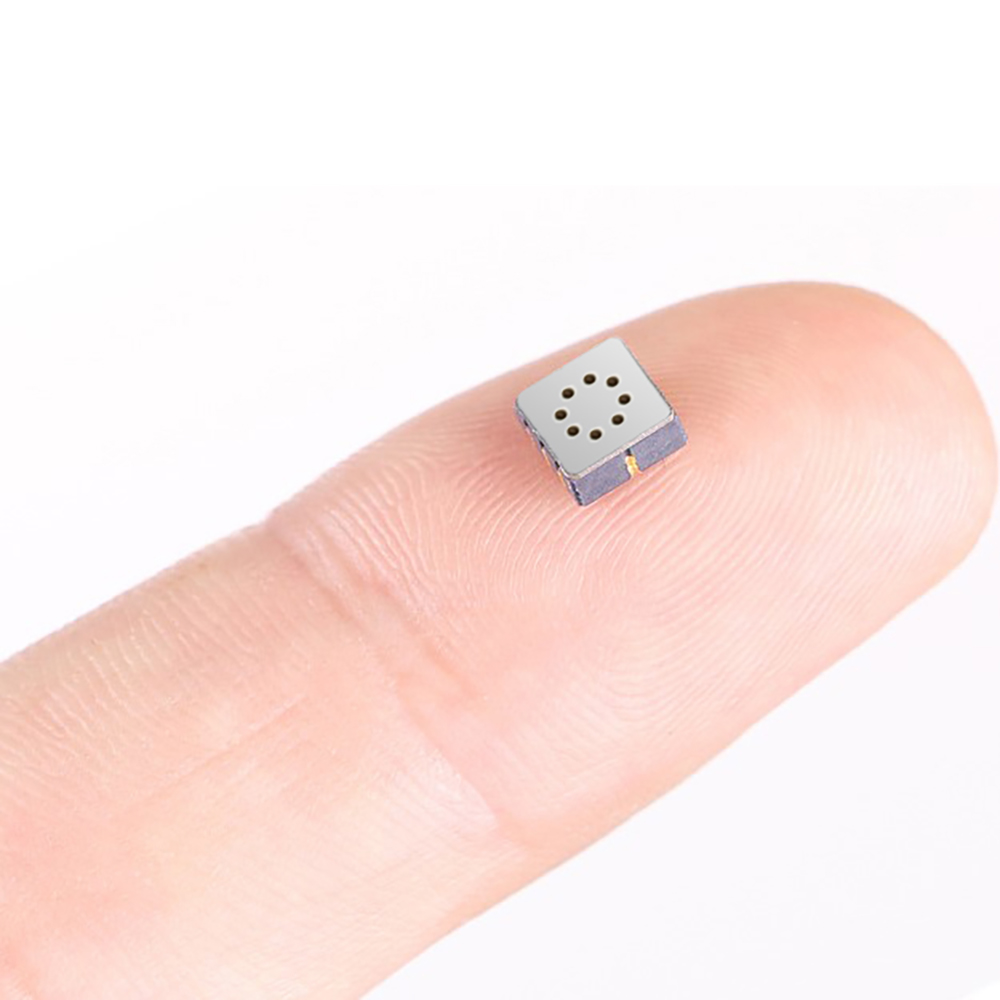

MEMS (Microelectromechanical Systems) is a multidisciplinary cross-field that integrates microelectronic technology, micro-mechanical technology and micro-nanometer machining technology, and MEMS gas sensors are one of the common applications of MEMS technology, which adopts micro-mechanical machining and semiconductor process technology to shrink the sensing element to the micron level, in order to realize the gas sensor. to the micron level to realize the detection and measurement of gaseous substances.

The basic principle of MEMS gas sensors is to utilize the sensing element to adsorb the gas molecules and then cause volume changes to change the electrical properties and other characteristics. Typically, the sensing elements in gas sensors are fabricated using micromachining technology to reduce them to the micron or even nanometer scale in order to achieve high sensitivity, high resolution and fast response. In addition, the sensors also include electronic components such as capacitors and resistors to convert the signals from the sensing element into electrical signals and output the corresponding gas concentration information through the processing circuit.

Application Scenarios of MEMS Gas Sensors

MEMS gas sensors have been widely used in environmental monitoring, industrial safety, healthcare and biology. Specifically, they can be used in the detection of indoor air quality, the concentration of harmful gases in industrial production processes, the detection of respiratory diseases in medical diagnosis, and the study of cell metabolism and respiratory activity in biology.

- In environmental monitoring, MEMS TVOC Sensor can detect indoor pollutants such as VOCs (Volatile Organic Compounds), CO2 (Carbon Dioxide), and PM2.5 (PM2.5) to improve indoor air quality and safeguard people’s health.

- In industry, the sensor detects harmful gases such as CO (carbon monoxide), H2S (hydrogen sulfide) and SO2 (sulfur dioxide) to ensure safety in the production process.

- In healthcare, MEMS gas sensors can assist in the diagnosis of respiratory diseases such as bronchial asthma and lung cancer, and improve the quality of life of patients by monitoring their respiratory rate, oxygen concentration and other parameters.

- In biological research, the sensor can be used to detect changes such as internal cell metabolism and respiratory activity, providing data support for cutting-edge research in biology.

Advantages and disadvantages of MEMS gas sensors

MEMS gas sensors have the following advantages over traditional gas detection methods:

- High sensitivity and high resolution: due to the use of micromachining technology, the sensitivity and resolution of the sensing element have been greatly improved.

- Fast response: the smaller the size of the sensing element, the faster the response speed, MEMS gas sensors can respond to changes in gas concentration within milliseconds.

- Multi-parameter detection can be realized: MEMS gas sensors can realize the detection of a variety of gas parameters, such as temperature, pressure, etc., by adjusting the structure and material of the sensing element.

- Small size and light weight: Due to the miniaturization of the sensing element, the size and weight of the MEMS gas sensor have been greatly reduced, making it easy to install and integrate.

Future Development Direction

With the continuous development and innovation of MEMS technology, MEMS gas sensors will also continue to evolve in the direction of high sensitivity, high accuracy, multi-parameter detection and intelligence. For example, in the design of sensing elements, new materials such as nanomaterials and functional materials can be used to improve the sensitivity and selectivity of the sensor; in the manufacturing process, new technologies such as integration and self-assembly can be used to improve the manufacturing efficiency of the sensor and reduce the cost; in the application of intelligence, emerging technologies such as wireless communication and cloud computing can be combined to realize remote monitoring, data sharing and other functions.

In summary, MEMS, as an emerging gas sensor detection technology, has a broad application prospect. Although there are certain technical limitations and higher prices, with the continuous development of science and technology, MEMS gas sensors will be further improved and innovated to bring more applications and value to the fields of environmental monitoring, industrial safety, healthcare and biology.