Nitrogen dioxide sensor FS01901

- high sensitivity, high stability, high resolution

- excellent anti-interference ability, with temperature compensation

- Excellent linear output

- Low power consumption, long service life

Principle of operation of the Nitrogen dioxide(NO2) sensor

The principle of operation of the Nitrogen dioxide sensor is based on an electrochemical reaction. When NO2 gas passes through the sensor, the gas molecules interact with the semiconductor material, resulting in changes in conductivity. These changes are converted into electrical signals by the micropump and delivered to the signal processing circuit for processing. The signal processing circuit amplifies, filters, and compares the collected electrical signals, and finally outputs a digital signal of NO2 gas concentration.

Nitrogen dioxide pollution and NO2 sensor technology

Nitrogen dioxide (NO2) is a common atmospheric pollutant, mainly from vehicle exhaust, industrial waste gas and air pollution.NO2 gas has an irritating odor and is harmful to human health and the environment. Therefore, the detection and control of NO2 is of great significance.

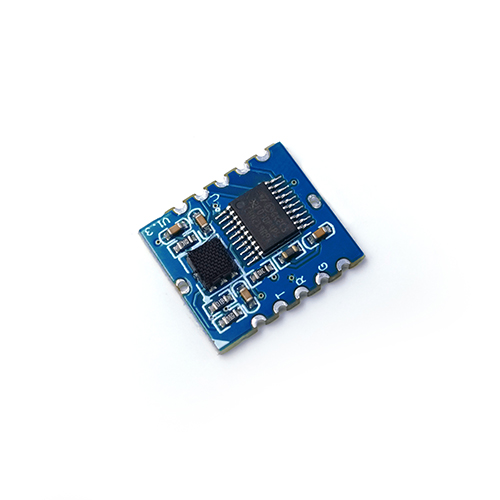

In recent years, the development of MEMS technology provides new opportunities for the research and application of Nitrogen dioxide sensor.MEMS (microelectromechanical system) refers to tiny mechanical structures, including sensors, actuators, controllers and so on, which are fabricated by using microelectronic fabrication technology. Sensors manufactured using MEMS technology have the advantages of high sensitivity, fast response speed and good stability, which can meet the requirements of high precision and high sensitivity.

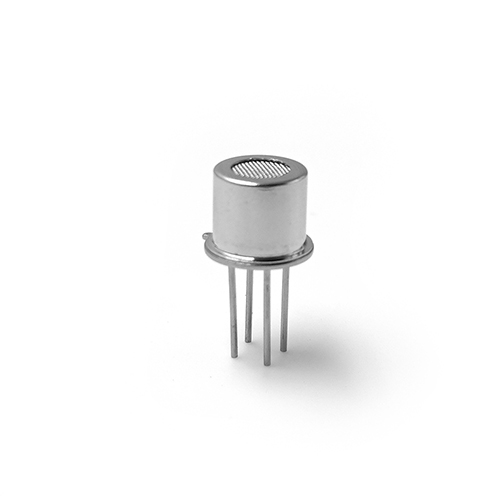

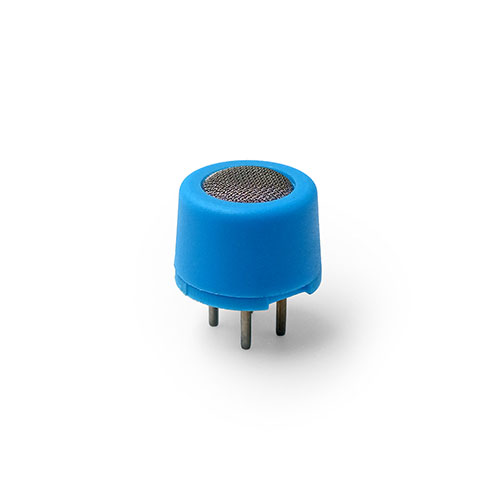

Nitrogen dioxide sensor is manufactured by MEMS technology, which mainly includes two parts: sensor circuit and micro pump. The sensor circuit is manufactured by semiconductor process, including PMOS and NMOS transistors, capacitors and resistors. The transistors and capacitors are connected to the gas under test. When NO2 gas passes through the sensor, the gas molecules interact with these components, resulting in changes in voltage and current in the circuit. These changes are converted into electrical signals by the micropump and sent to the signal processing circuit for processing.

Specificities

The advantages of Nitrogen dioxide sensor include high sensitivity, fast response speed, good stability, strong anti-interference ability and so on. Due to its small size, light weight, and low energy consumption, Nitrogen dioxide sensor can be integrated into micro devices for portable detection. In addition, NO2 sensor can be combined with other sensors to realize multi-parameter monitoring and control.

Nitrogen dioxide sensor has a wide range of applications, for example, it can be used in automobile exhaust emission detection, industrial exhaust emission detection, environmental monitoring and other fields. In addition, NO2 sensor can also be used in medical, aerospace and other fields to realize real-time monitoring and control of NO2 concentration in the environment.

Applications

1.Gas detectors, instrumentation equipment

2.Industrial production safety

3.Automobile exhaust emission detection

4.Toxic and hazardous gas detection

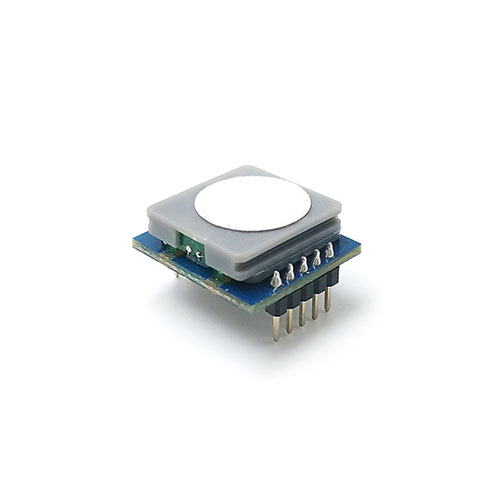

Specifications

Parameter type | Parameter indicators |

Detection type | Nitrogen dioxide gas |

Detection Principle | Three-electrode electrochemistry |

Detection range | 0~20ppm |

Loading | 200pmm |

Resolution (of a photo) | 0.1ppm |

Data Accuracy | Inaccuracies≤±3%FS |

Response time | T90≤30s |

Operating voltage | DC 3.7V~5.5V |

Operating Current | <0.3mA(@5V Electricity supply) |

Preheating time | 3min |

Detection frequency | Data is updated 1 time per second (default). |

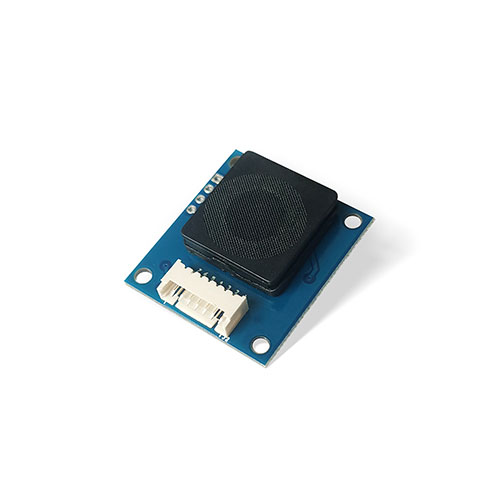

Default Output Method | UART (3.3V_TTL Voltage level) |

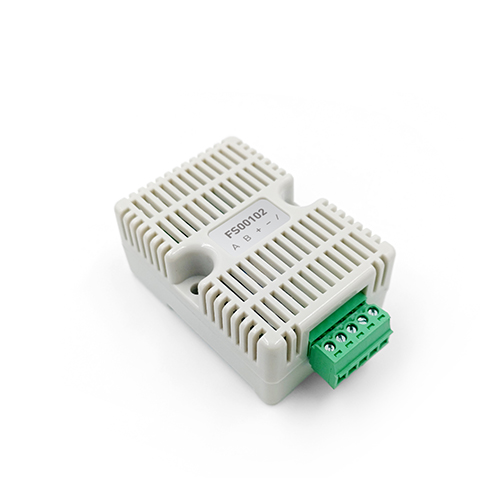

Reserve Output Method | Modbus (RS485) |

Service life | 2 years (on air) |

Reference size | 32.3×32.3×16.5 mm |