Application fields of Industrial co2 monitor

Do you know how much carbon dioxide is in the air? Do you know what impact carbon dioxide has on our lives and the environment? Industrial co2 monitor is an instrument that can measure the concentration of carbon dioxide in the air in real time. Its core component is mainly CO2 sensor. It is not only used in industry but also has wide applications in agriculture, environmental protection, medical care, education and other fields, which is of great significance. and value. This article will introduce the working principle, performance characteristics, and application scenarios of Industrial co2 monitor.

How does Industrial co2 monitor work?

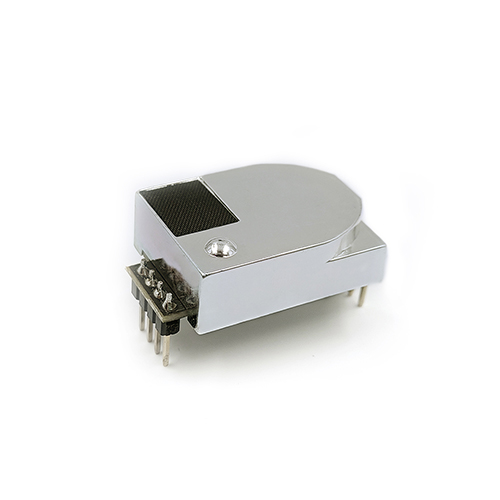

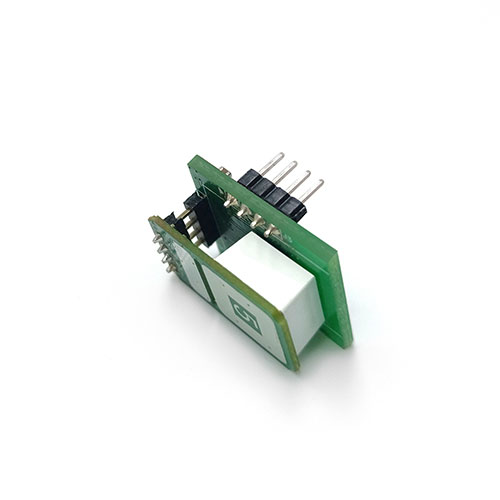

There are two main working principles of Industrial co2 monitor: non-dispersive infrared (NDIR) and electrochemical (EC). Both principles use the interaction of carbon dioxide molecules with light or electricity to measure their concentration, but the specific implementation methods and effects are different. Let’s take a look at them separately.

The non-dispersive infrared detector uses the absorption characteristics of infrared light by carbon dioxide molecules to quantitatively analyze carbon dioxide in the air through an optical system composed of infrared light sources, optical filters, detectors, etc. This kind of detector has the advantages of high accuracy, high stability, long life, and low maintenance cost, but it also has the disadvantages of large size, high price, and vulnerability to temperature and humidity.

The electrochemical detector uses the redox reaction of carbon dioxide molecules on the electrode surface to reflect the carbon dioxide concentration in the air through current signals. This kind of detector has the advantages of small size, low price, and fast response speed, but it also has the disadvantages of low accuracy, poor stability, short life, and the need for regular calibration.

To sum up, non-dispersive infrared detectors are suitable for occasions with high requirements on accuracy and stability, such as laboratories, greenhouses, breweries, etc.; electrochemical detectors are suitable for occasions with high requirements on response speed and price. Such as home, office, classroom, etc.

Industrial co2 monitor performance characteristics

Measuring range: refers to the maximum and minimum carbon dioxide concentration that the Industrial co2 monitor can measure, usually in ppm (parts per million) or % (percentage). Different application scenarios have different requirements for the measurement range, such as Greenhouses generally require 0-5000 ppm, while urban air generally requires 0-1000 ppm.

Accuracy: refers to the error range between the detector’s measurement results and the true value, generally in ±ppm or ±%. The higher the accuracy, the smaller the error, and the more reliable the measurement results.

Resolution: refers to the minimum change value of carbon dioxide concentration that the detector can distinguish, usually in ppm or %. The higher the resolution, the more sensitive the detector is and can capture more subtle changes.

Response time: refers to the time it takes for the detector to receive the carbon dioxide signal and output the result, usually in seconds or milliseconds. The shorter the response time, the faster the detector can reflect the current situation in a timely manner.

Stability: refers to whether the performance parameters of the detector remain unchanged or change very little during long-term use. The higher the stability, the more reliable the detector and the lower the maintenance cost.

Temperature and humidity compensation: means that the detector can automatically adjust its internal parameters according to changes in ambient temperature and humidity to eliminate the impact of temperature and humidity on the measurement results. The better the temperature and humidity compensation, the more accurate the detector will be.

Display mode: refers to how the detector displays the measurement results to the user. Common ones include LCD display, LED display, digital tube display, etc. Different display modes have different characteristics such as clarity, brightness, and color.

Output mode: refers to how the detector transmits measurement results to external devices. Common ones include analog signals, digital signals, wireless signals, etc. Different output modes have different compatibility, stability, security and other characteristics.

Alarm function: means that the detector can emit sound, light or other prompts when the carbon dioxide concentration exceeds the set threshold to remind the user to take corresponding measures.

Wide application of Industrial co2 monitor

Industrial production: Industrial co2 monitor can be used to monitor and control process parameters, such as carbon dioxide content during fermentation, to improve product quality and efficiency. For example, in beer brewing, carbon dioxide detectors can be used to control the pressure and temperature in the fermentation tank to ensure the taste and aroma of the beer.

Agricultural planting: Carbon dioxide detectors can be used to monitor and regulate carbon dioxide levels in greenhouses to promote plant growth and increase yields. For example, in vegetable cultivation, carbon dioxide detectors can be used to control ventilation and fertilization in the greenhouse to ensure the nutrition and quality of vegetables;

Environmental monitoring: Carbon dioxide detectors can be used to monitor urban air quality and greenhouse effect to assess environmental conditions and formulate policy measures. For example, in urban traffic, carbon dioxide detectors can be used to monitor the amount of carbon dioxide emitted by vehicles and adjust traffic lights and traffic restrictions based on real-time data;

Educational and scientific research: Carbon dioxide detectors can be used to conduct various experiments and teaching to cultivate students’ scientific literacy and innovative abilities. For example, in geographical experiments, carbon dioxide detectors can be used to observe and measure the amount of carbon dioxide affected by climate change in different regions.

This article briefly introduces the principles, characteristics and applications of Industrial co2 monitor, aiming to provide readers with some basic knowledge and information. The carbon dioxide detector is a practical instrument that plays an important role and value in various fields. I hope this article can inspire and help readers.