Catalytic gas sensor working principle

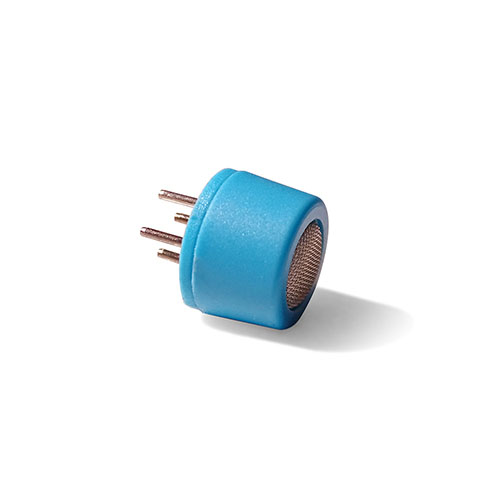

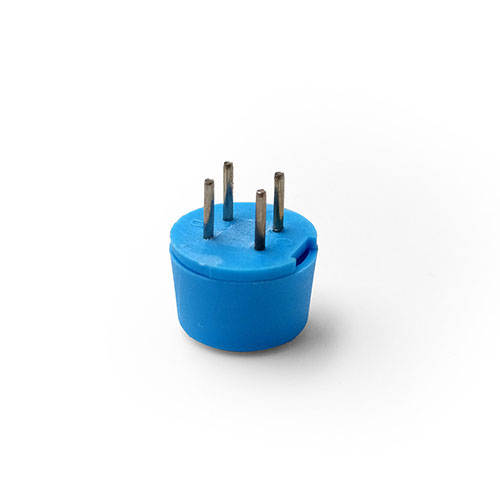

Catalytic combustible gas sensor definition

Catalytic combustible gas sensor utilizes the thermal effect principle of catalytic combustion to form a measuring bridge by pairing detecting elements and compensating elements. Under certain temperature conditions, combustible gas will burn without flame on the carrier surface of detecting elements and under the action of catalyst, and the carrier temperature will rise. The resistance of the platinum wire through it is also increased accordingly, so that the balance bridge is out of balance, and the output of an electrical signal is proportional to the concentration of the flammable gas.

By measuring the magnitude of the change in the resistance of the platinum wire, the concentration of flammable gas is known. It is mainly used for the detection of combustible gases, with good linear output signal, reliable index, affordable price, and will not cross infection with other non-combustible gases.

Catalytic gas sensor working principle

The catalytic combustion gas sensor is based on the thermal oxidation of combustible gas or vapor on the surface of the heat medium, and measures the heat released during the combustion process through the combustion gas. The sensor is an unbalanced bridge circuit composed of two matching sensitive elements (sensor elements) and two fixed resistors of equal resistance. The two sensitive elements are symmetrical hot-wire carrier catalytic elements, one is an active element (active element) and the other is a passive element (inactive element), both of which are electrically heated (with electrothermal effect) to form the two bridge arms of the Wheatstone bridge, and two fixed resistors with equal resistance constitute the other two bridge arms of the Wheatstone bridge.

When the combustible gas contacts the sensor, the active component catalyzes the oxidation of the gas, releases the heat of reaction, and heats the active component, causing its temperature to rise and the resistance value to increase, while the passive component remains unchanged, the measurement bridge loses balance, and a voltage signal output is generated. At this time, the output voltage signal is proportional to the concentration of the combustible gas. The sensor responds quickly to combustible gases as long as the active element (active element) remains in good condition.

Advantages and disadvantages of Catalytic combustible gas sensor

Catalytic combustion gas sensors are usually stable, have good repeatability, and are not affected by ambient temperature and humidity, and have been widely used in many industrial fields. However, the reliability and sensitivity of the Catalytic combustible gas sensor are easily affected by certain chemical components in combustible gases, such as silicon vapor, lead compounds, chlorides, halogenated hydrocarbons, sulfides, hydrogen sulfide and other acid gases and other environmental pollution. The so-called sensor poisoning failure phenomenon occurs.

Catalytic combustible gas sensor development application

Originally created in the 1960s by British scientist and inventor Alan Baker, the Catalytic combustible gas sensor was originally designed for the long-used flame safety lights and Canari technology. Sensors of this principle are used today in industrial and underground applications such as mines or tunnels, refineries and oil drilling rigs.