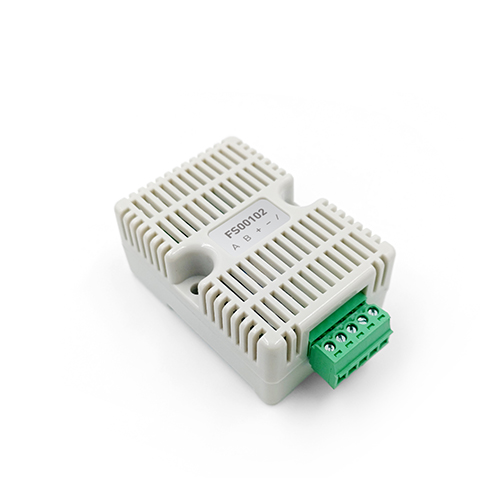

Battery Thermal Runaway Monitoring Sensor FS02203

This solution is capable of effectively monitoring various metrics, such as CO2+CO emissions, temperature, and pressure, that indicate thermal instability in batteries before it triggers. The measurement signals can be transmitted to BMS via CAN communication.

Battery Thermal Runaway Monitoring Sensor FS02203 Introduction

FS02203 is a battery thermal runaway monitoring sensor that can effectively detect the indicators such as CO2+CO, temperature, and pressure released before the occurrence of thermal runaway in batteries and transmit the measurement signals to BMS via CAN communication. This solution has significant features such as accurate measurement, rapid response, low cross-interference, low power consumption, and long lifespan.

Battery Thermal Runaway Monitoring Sensor FS02203 Features

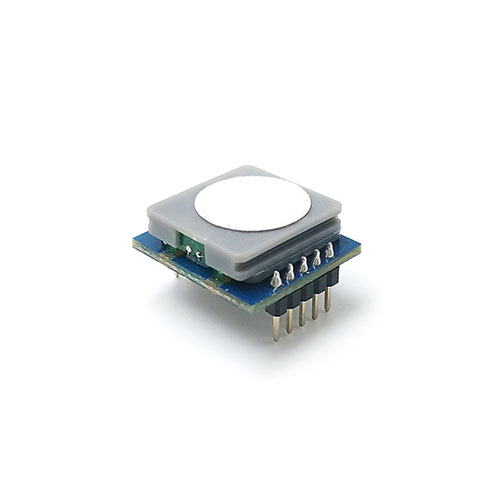

Carbon dioxide (CO2) measurement is achieved using non-dispersive infrared absorption technology (NDIR), with an accuracy of ±(50ppm+5% reading) within a measurement range of 0-10000ppm. The response time is fast, with T90<15s, and there is no cross-interference from other gases. The ultra-low-power mode can reach μA level, and its lifespan can reach up to 15 years.

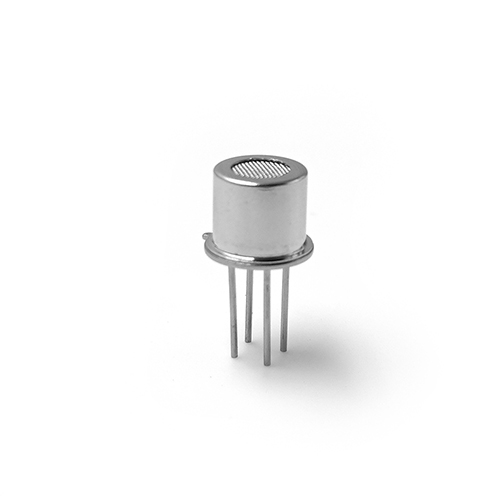

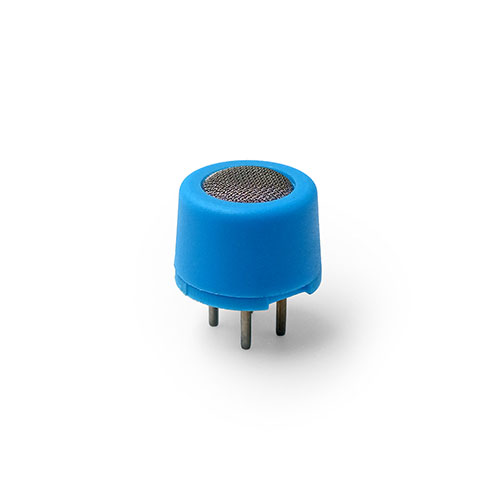

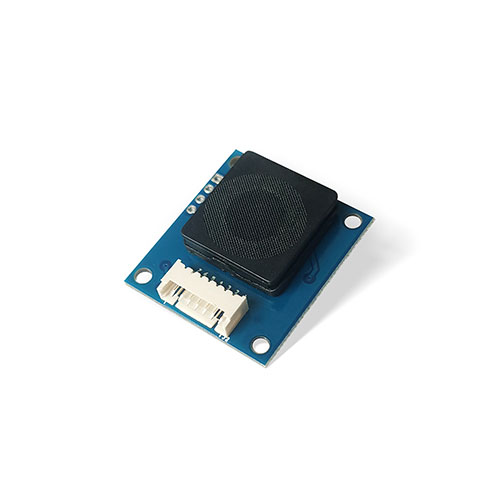

The measurement of carbon monoxide (CO) uses the MEMS production line developed independently, which produces metal oxide semiconductor (MOX) sensors. The electronic nose technology is used to select MOX sensors for good CO gas selectivity, low sensitivity to temperature and humidity, and stable detection signals. It can also extend to detect other gases according to the manufacturer’s thermal runaway research results. The lifespan of the semiconductor CO sensor is over 15 years, and it has good resistance to corrosion by organosilicon gases.

The MEMS MOX sensor measures CO, with small sensitivity to temperature and humidity and stable detection signals. It can expand to detect multiple gases, and its lifespan is more than 15 years, with good corrosion resistance of organosilicon gases.

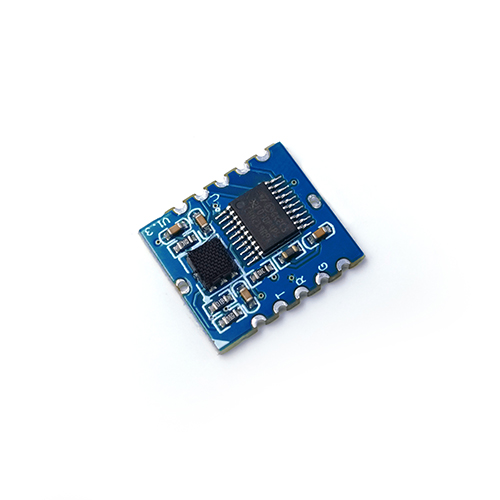

The module adopts mature circuit design for automotive regulations and can adapt to harsh onboard environments. CAN real-time communication is supported, and the protection level can reach IP65.

Application

1.New energy vehicles, trams

2.Energy storage power station, power system

3.Battery Safety Monitoring Equipment

Specifications

Detection principles | CO2:(Dual Beam NDIR) Temperature: NTC |

Detection parameters | CO2, CO, temperature, pressure (expandable to customize CH4+H2). |

Detection ranges | CO2: 0ppm-10000ppm |

Resolution | 1ppm |

Detection accuracy | CO2:±(50ppm+5% reading) |

Data refresh rate | ≤1s |

Response time | T90<15s |

Output mode | CAN/LIN/UART/analog voltage |

Operating conditions | 40℃~+85℃, 0~99%RH (non-condensing). |

Storage conditions | -40℃~+110℃, 0~99%RH (non-condensing). |

Power supply voltage | 9~16VDC, with standard voltage at +12VDC. |

Average working current | ≤100mA @+12VDC (supporting low-power mode start-up and 24-hour online monitoring). |

Static current | <100uA in sleep mode |