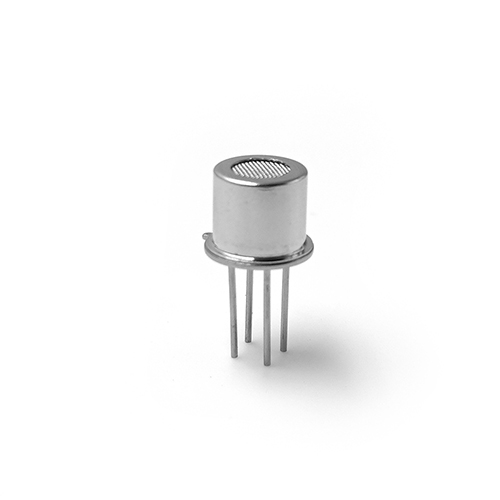

Metal oxide semiconductor gas sensor working principle

Metal oxide semiconductor gas sensor is a common gas sensor, which can detect formaldehyde, hydrogen, natural gas and other gases in the air. The principle is to use the electrical properties of oxide semiconductor materials. When gas molecules react with their surface, their resistance value will be changed to realize gas detection.

Metal oxide semiconductor gas sensor working principle

The metal oxide semiconductor gas sensor uses the adsorption of the measured gas to change the conductivity of the semiconductor, and the alarm circuit is activated through the comparison of the current change. Semiconductor gas sensors are divided into N-type and P-type. When the N-type gas sensor detects methane, carbon monoxide, natural gas, coal gas, liquefied petroleum gas, acetylene, hydrogen and other gases, its resistance value decreases; when the P-type gas sensor detects combustible gases, the resistance value will increase, and when it detects oxygen, chlorine and carbon dioxide and other gases, its resistance value will decrease.

Taking P-type SnO, the gas-sensitive material as an example, oxygen is first adsorbed on the surface of the SnO, film for physical adsorption. Oxygen then captures Sn0, the internal vacancies, and becomes negatively charged 0 and 0-07 below 150°, and 0~ above 150°. As the temperature increases, a reaction occurs: 0,+2e~= 20ads

The negative charge increases, and a defect layer is formed inside the SnO, leading to a decrease in conductivity: When the SnO film is placed in a reducing gas, the electrons captured by oxygen return to the inside of the SnO, resulting in a decrease in the height of the potential barrier layer, thereby increasing the conductivity. Sn0, after the surface is in contact with the reducing gas, the surface active center Oads interacts with the reducing gas to release electrons, the electron density in the conduction band of the tin dioxide material increases, the resistance decreases, and the detection of the gas is realized through the change of the electrical signal intensity.

What materials are suitable for semiconductor gas sensor?

1.Raw materials are easy to obtain;

2.It has good adsorption capacity for oxygen and target gas at lower temperature, the two have good chemical reaction capacity, and have good desorption capacity for reaction products at this temperature;

3.after forming with other auxiliary materials, good compatibility, chemical stability, and suitable micro-defect conductivity.

The common materials that meet this condition are tin dioxide, tungsten oxide, indium oxide, zinc metasannate, etc.

Future prospects of Semiconductor gas sensors

In many gas sensor categories, semiconductor sensor is a very promising gas sensor. The reason is that its working principle and sensing process are extremely simple, that is, gas information can be changed into electrical signals in just one step; Secondly, the sensor carrier is stable; And the cost is cheaper. The above characteristics not only provide a clear path and space for its evolution, but also provide economic feasibility for large-scale deployment in the future. Fosenser manufactures several Semiconductor gas sensor models, please contact us if you need them.