Natural gas leak monitor

With the development of economic construction and gas industry, natural gas has been widely used in people’s life, work and travel. It can improve the city’s energy structure, protect the environment and reduce air pollution. But what follows is that urban gas leakage will bring great threats to people, affecting people’s lives, work and even lives.

According to natural gas news reports, gas accidents often occur in daily life, and the overall accident rate is still very low. However, once an accident occurs, it not only causes heavy economic losses, but also poses a threat to people’s life safety.

Analyzing the types of accidents, gas explosion accidents caused by natural gas leakage account for a large proportion. How to quickly and accurately locate and monitor natural gas leaks and improve the leakage early warning and prevention capabilities of the natural gas system has attracted great attention from the safety department.

The chemical properties of natural gas are flammable and explosive gases, with a low boiling point and a smaller relative density than air. The main component of natural gas is organic compounds such as methane (CH4). Therefore, natural gas leakage detection is essentially the detection of methane gas volume fraction. At present, the monitoring methods of Natural gas leak monitor mainly include fiber absorption method, optical interference method, thermal catalysis method, etc.

1. Optical fiber absorption method

Optical fiber absorption method is the focus of current research and application and the development direction of natural gas detection technology. Its basic principle is the Beer-Lambert theorem. Light is made up of photons, and when a gas is illuminated by a light beam, the gas molecules selectively absorb photons of certain frequencies. Absorption of photons by gas molecules will cause the intensity of the transmitted light to decrease. When parallel light of a specific wavelength passes through a gas of a certain thickness, the intensity of the emitted light has a certain functional relationship with the gas volume fraction. This functional relationship can be used to realize the volume of methane gas. Score detection.

2. Optical interference method

The scattered light emitted by the light source reaches the plane mirror after being focused by the condenser. Part of the beam is reflected by the plane mirror and reaches the refracting prism through the air in the air chamber. The refracting prism refracts it back to the air chamber on the other side and then returns to the plane mirror and refracts to the rear surface. On the reflective film, it is reflected to the prism through the reflective film and then deflected into the telescope system. After the other part of the light beam is refracted into the plane mirror, it is reflected by the reflective film on the rear surface. The methane passing through the air chamber is reflected by the refracting prism and then returns to the plane mirror through the methane chamber. After being reflected by the plane mirror, it enters the reflecting prism with the above part of the light beam and is deflected by the deflection prism. Folds into the telescope system.

As a result of the optical path difference, interference fringes are produced on the focal plane of the objective lens, and the interference fringes can be observed through the eyepiece. When the methane chamber and the air chamber are both filled with the same gas, the interference fringe position does not move. However, when methane is pumped out of the methane chamber, the interference fringe moves a certain distance relative to the original position because the medium through which the beam passes changes. By measuring this displacement, the amount of methane in the air can be known.

3. Thermal catalysis method

The thermocatalytic method is a detection method based on the ability of a specific catalyst to burn methane under certain conditions. The principle is that when air containing methane encounters a platinum wire with a hot catalyst (the platinum wire is heated to a certain temperature by the working current), the methane contacts the catalyst and burns smokelessly, releasing combustion heat, and the temperature of the platinum wire increases accordingly. , resulting in a significant increase in the resistance of the platinum wire, outputting a certain voltage, and detecting the methane gas volume fraction based on the different output voltages.

The advantage of the thermocatalytic method is that the performance of the carrier catalytic element is relatively stable in an environment with a low methane gas volume fraction, the zero point drift is small, and the accuracy is high. However, when the methane volume fraction is higher than 9.5%, methane cannot be fully burned, the resistance change of the carrier catalytic element is small, and the sensor indicator output data becomes smaller, which can easily cause measurement errors). In addition, changes in the external environment, usage conditions, and the decrease in the catalytic activity of the component itself will increase the detection limit of the sensitive component, thereby reducing the accuracy of the detection data. Therefore, the thermocatalytic method is more suitable for situations where the methane volume fraction is low (generally less than 4%).

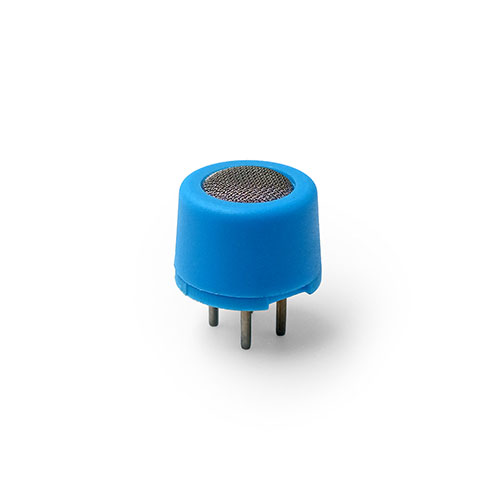

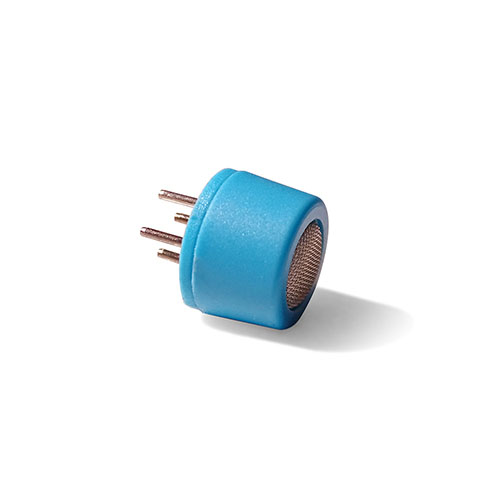

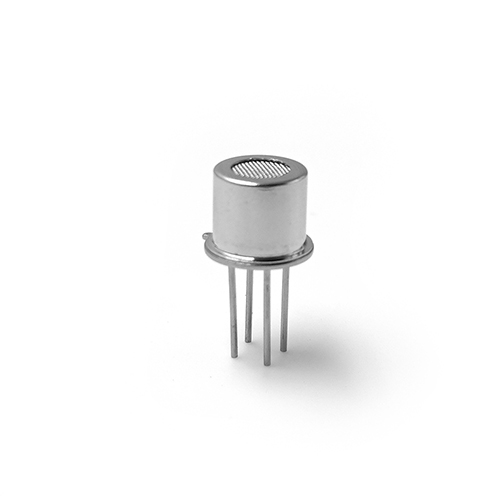

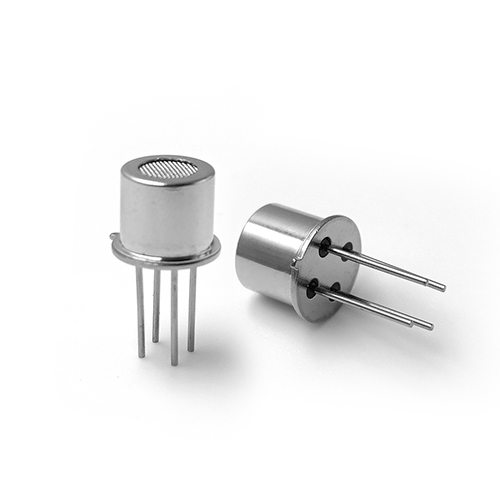

Natural gas leak monitor manufacturers

Fosensor is a manufacturer of gas sensors and gas detectors. We not only provide Natural gas leak monitors but also Methane sensors, the core of the detectors. We can also customize R&D and production according to customer needs. Fosensor has twenty years of production and R&D experience. If you Please feel free to contact us if necessary.