NDIR CH4 sensor principle analysis

The NDIR CH4 sensor is a commonly used gas sensor for detecting the concentration of methane gas. Its working principle is to make use of the property that methane molecules absorb infrared rays of specific wavelengths. The sensor emits infrared light of a specific wavelength, and when methane is present in the gas being detected, the methane molecules will absorb the infrared light of a specific wavelength, which leads to a change in the detection signal. The concentration of methane gas can be calculated from the difference in the detected signal.

Working principle of NDIR CH4 sensor

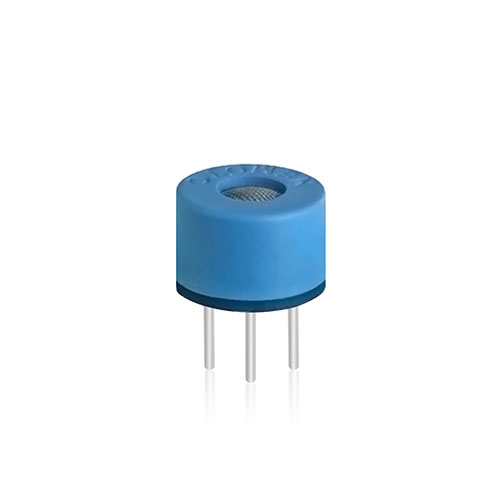

The infrared methane sensor consists of an infrared source, an infrared window, a gas chamber, a detector, and a signal amplifier. The infrared rays emitted by the sensor enter the gas chamber through the infrared window, the methane molecules in the detected gas absorb part of the infrared rays, and the rest of the infrared rays go through the detector to reach the signal amplifier and amplify the output. The detector is able to detect the difference in intensity of the infrared rays and thus calculate the concentration of methane gas.

Advantages of infrared methane sensor

1. It adopts the non-scattering principle, which can only detect specific gases and will not be interfered with by other gases, with high detection accuracy.

2. The sensor has no moving parts and is not easily damaged, so it has high stability and reliability.

3. The sensor has a long service life due to its low power consumption.

Features of infrared methane sensor

1. It can detect the concentration of methane gas ranging from a few milligrams per cubic meter to more than 10% for different applications.

2. The sensor can be used in conjunction with a variety of systems, such as alarm systems and vibration systems.

3. Due to the fast response speed of the sensor, it can quickly detect gas leakage and effectively prevent accidents.

Comparison of infrared methane sensor and catalytic methane sensor

Catalytic methane sensor: adopts Wheatstone bridge structure, detects the gas through the principle of chemical reaction with the participation of catalyst. Because of the simple structure and low material cost, the sensor is inexpensive. Because it is a chemical reaction and a catalyst must be involved, many of the sensor’s properties are affected. For example, due to insufficient combustion reaction, some substances cover the catalyst to block its participation in the reaction, resulting in sensor failure. For example, silicone-containing compounds, lead-based compounds, halogenated hydrocarbons, hot organic acids, etc. entering the sensor or direct exposure of the sensor to acidic gases can cause sensor poisoning. The life of the sensor is also affected by the catalyst and can only last up to two years. Furthermore, the sensor needs to be serviced (calibrated for zero and sensitivity) once a reaction has taken place. As the chemical reaction must have oxygen involved, the oxygen content of the environment also has an impact on the detection value, oxygen concentration below 16% of the measured value is low, and other factors lead to large sensor error. Sensor detection range is only 0-100% LEL, and can only do quantitative detection, measurement of the environment in the integrated combustible gases, to play the role of alarm, but not qualitative detection.

Infrared methane sensor: based on Lambert-Bill’s law, that is, different gases absorb the principle of specific wavelengths of light, the use of optical components combined with the free diffusion structure design to detect the gas. Infrared radiation of matching frequency is absorbed, resulting in a specific absorption band and an infrared spectrum. The infrared absorption spectrum provides both qualitative and quantitative information and can detect not only PPM levels but also 100% VOL. The lifetime of the infrared light source is typically 10 years, so the sensor lifetime is at least 10 years. As the sensor is optical, it will automatically zero when there is no gas being measured, so it is generally recommended to test the sensor once a year (and calibrate it if necessary). Because of the different absorption spectra of different gases, infrared detection is not interfered with by other gases.

Application range

NDIR CH4 sensor has a wide range of applications. It is generally used for methane gas detection in mining, petrochemicals, aviation, and aerospace. In coal mines, petrochemicals, gas, and other enterprises, it is commonly used as a monitoring system for hazardous materials leakage and plays an important role in early warning, alarm, and accident handling.