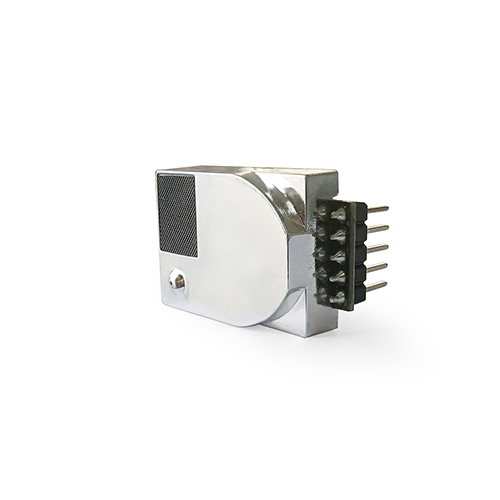

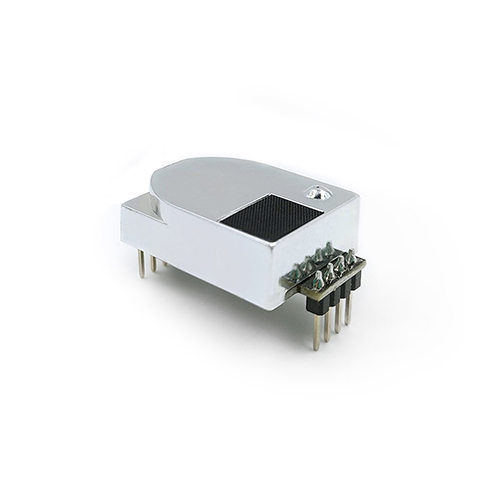

NDIR co2 sensor

Preface

Asymmetric molecules (containing different atoms) can absorb infrared rays at specific wavelengths. This specific absorption band is certain and standard for a certain molecule, and is called a “material fingerprint.”

Specifically, infrared rays are electromagnetic waves within a certain wavelength range. When it encounters a specific medium during its transmission to the surroundings, it can be absorbed or transmitted by the medium. Absorption spectra cannot be generated for symmetrical diatomic molecules composed of the same kind of atoms, such as O2, N2, H2, etc. or single-atom molecules such as He, Ne, etc. However, molecules with different atomic compositions and containing dipole moments can emit radiation waves of specific wavelengths. The technology for measuring gas concentration based on this principle is called NDIR technology.

With the development of infrared light sources, sensors and electronic technology, NDIR, as a fast and accurate gas analysis technology, has been widely used in gas concentration detection. For CO2 detection, the NDIR detection method is recognized as the most effective analysis method. By using NDIR co2 sensor and electrically modulated light source, and using low-power embedded system circuits, the sensor has advantages in size, power consumption, performance, and price that are unmatched by detection principles such as electrochemistry and semiconductors.

NDIR non-dispersive infrared principle

When infrared light passes through the gas to be measured, these gas molecules absorb infrared light of a specific wavelength, and the absorption relationship obeys the Lambert-Beer absorption law. Therefore, for a variety of mixed gases, a narrow-band filter suitable for analyzing the absorption wavelength of the gas is installed in front of the sensor or infrared light source. The signal changes of the sensor can reflect the changes in the concentration of the measured gas, thereby analyzing the specific components of the mixed gas.

Taking CO2 analysis as an example, the infrared light source emits infrared light of 1-20um. After being absorbed by a gas chamber of a certain length, it passes through a narrow-band filter with a wavelength of 4.26μm, and an infrared sensor monitors the intensity of the infrared light with a wavelength of 4.26um. , to express the concentration of CO2 gas.

Key Technologies for NDIR Detection

When designing the optical system part of the NDIR co2 sensor, in order to reduce the attenuation of the weak signal of the infrared sensor and interference from external signals, the preamplifier circuit is also placed on the optical components, and certain electromagnetic shielding measures are taken. In order to make the gas infrared absorption signal have better resolution, the infrared light source, gas chamber, and infrared detector should be set on the same optical axis during structural design. In addition, in order to make the signal large enough, elliptical or parabolic reflectors can be used. The infrared light source is powered by a steady current, and the supply voltage and current vary depending on the light source used.

When working, the sensor emits periodic infrared light according to the preset modulation frequency. The infrared light emitted by the infrared light source is incident on the measuring gas chamber through the window material. The measuring gas chamber continuously passes the measured gas into the measuring gas chamber by the sampling air pump. The gas absorbs infrared light of a specific wavelength, and the infrared light transmitted through the measuring gas chamber is detected by an infrared detector. Due to the effect of modulating infrared light, the infrared sensor outputs an AC electrical signal, which is amplified by the subsequent preamplifier circuit and then passes through a high-precision amplification and rectification circuit to obtain a DC signal corresponding to the concentration of the measured gas and send it to the measurement and control system for processing. There is a temperature sensor inside the infrared sensor to detect the temperature of its working environment. The infrared sensor signal passes through the measurement and control system and is processed by software such as digital filtering, linear interpolation and temperature compensation to give the gas concentration measurement value.

In this process, the following key technologies were adopted:

1.Infrared light source and its modulation

New electrically modulated infrared light sources such as pulsIR and reflectIR can heat up and cool down very quickly. A transparent window is installed on the emission window of the infrared light source. On the one hand, it can ensure that the wavelength of the emitted infrared light is within a specific range, and is suitable for measuring conventional gases such as CO2, CO, CH4, NO, SO2 and other gases. In addition, it can also prevent the influence of the external environment on the temperature of the light source.

2.Coated air chamber

It adopts a structure in which the air chamber is separated from the external support. During installation, you only need to fix the air chamber in the center of the support structure. This structural design ensures that the component is easy to load, disassemble, and replace; at the same time, because it is separated from the external support, the influence of external conditions is further reduced, allowing the sensor to adapt to work in complex environments. In addition, some sensors that require a long air chamber were originally very difficult to process with the coating process using previous methods. This method will be very easy and the cost will be greatly reduced. The traditional air chamber adopts an integrated design with the external support, which has the advantages of easy manufacturing and installation, but is greatly affected by external temperature fluctuations.

3.Infrared detector

Infrared detector is the core component of NDIR gas sensor. The measurement accuracy largely determines the performance of the sensor. The research uses a high-sensitivity infrared detector, with narrow-band interference filters for different gases fixedly installed on its package, which can realize the measurement of different gases. In order to ensure that the infrared detector gets a strong and stable signal, an orientation axis of the infrared detector can be designed. Even if the position of the infrared detector welded on the preamplifier board has a certain deviation, the sensor can ensure that it is in the same position as the infrared light source and the air chamber. on the same optical central axis.

The signal generated by the infrared detector receiving infrared light is very weak and is extremely susceptible to external interference. Therefore, a stable and reliable preamplifier circuit is the key. It is best to use a high-precision, low-drift analog amplification circuit and a narrow-band filter circuit. The preamplifier circuit has the characteristics of high precision, small drift and fast response. The preamplified signal passes through the secondary amplifier circuit to directly output a signal corresponding to the gas concentration, and is sent to the measurement and control system. The gas concentration is obtained after nonlinear correction and compensation.

4.Sensor measurement and control system

In order to realize the measurement, control and automatic calibration functions of the NDIR gas sensor, a suitable microcontroller is needed to manage the sensor. The sensor measurement and control system can directly obtain the concentration of the measured gas by collecting infrared output signals and measuring standard gas curves, and using nonlinear correction algorithms.

By using the above technology, the structure of the NDIR co2 sensor will be greatly simplified compared to previous instruments, the power consumption of the instrument will also be greatly reduced, and the cost of the sensor will be less than 1/4 of previous technologies. At the same time, this type of sensor can be modularized and standardized, can achieve high output in a short time, is suitable for large-scale mass production, and can be widely used.