Environmental monitoring in pharmaceutical industry

Environmental monitoring is very important in the production process of pharmaceutical companies. By monitoring the production environment, the safety, hygiene and quality of the production process can be ensured. This handout introduces the basic principles and methods of environmental monitoring in the pharmaceutical industry.

Environmental monitoring in pharmaceutical industry Objectives

1.Temperature monitoring

Temperature is a very important parameter in the pharmaceutical production process. The production of different drugs requires a suitable temperature environment, and too high or too low a temperature may have an adverse effect on the quality of the drug. Therefore, pharmaceutical companies need to monitor the temperature of the production environment in real time to ensure that the temperature is within the appropriate range.

2.Humidity monitoring

Humidity is another important parameter to monitor. The production of different drugs requires a suitable humidity environment, too high or too low humidity may have a negative impact on the quality of the drug. Pharmaceutical companies need to regularly monitor the humidity of the production environment and take appropriate control measures to keep the humidity within the appropriate range.

3.Pressure monitoring

In some pharmaceutical processes, gas control and ventilation are required. Therefore, pharmaceutical companies need to monitor the pressure of the production environment in real time to ensure that the pressure is within the appropriate range to ensure the quality and safety of the pharmaceutical process.

4.Ventilation monitoring

Ventilation is an essential part of the production environment in pharmaceutical companies. Ventilation can keep fresh air flowing in the production environment and reduce the contamination of harmful gases and microorganisms. Pharmaceutical companies need to monitor the operation of the ventilation device to ensure that the ventilation effect meets the standard requirements.

Environmental monitoring in pharmaceutical industry methodology

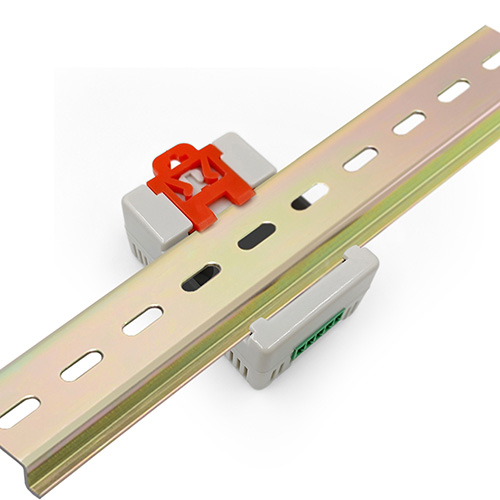

1.Sensor monitoring

Pharmaceutical companies can install various sensors in the production environment, such as Temperature and Humidity Sensor, Pressure Sensor, etc., through which the environmental parameters are monitored in real time. The sensors can transmit the monitored data to the monitoring system for real-time monitoring and data logging.

2.Monitoring System

Pharmaceutical companies can use a specialized monitoring system to monitor the production environment. The monitoring system can receive data from the sensors and perform real-time monitoring and data analysis. The monitoring system can also be set up alarm function, when the environmental parameters are out of the set range, it can remind the relevant personnel to deal with it in a timely manner.

3.Sample collection and testing

Pharmaceutical companies can regularly collect samples from the production environment and conduct testing and analysis. Through sample testing, it is possible to understand whether there are harmful gases, microorganisms and other pollutants in the environment, and whether the environmental parameters are within the acceptable range.

Monitoring requirements and control measures

In order to ensure the safety and quality of the production environment in a pharmaceutical company, control measures need to be taken based on the monitoring results. The following are some common monitoring requirements and control measures:

1.Temperature and humidity control

Pharmaceutical companies need to set the appropriate temperature and humidity range according to the characteristics of drug production, and to ensure that the temperature and humidity of the production environment is stable within the set range.

2.Pressure control

Pharmaceutical companies need to set the appropriate pressure range, and keep the pressure of the production environment is stable within the set range.

3.Ventilation management

Pharmaceutical companies need to regularly check the operating status of ventilation equipment to ensure that the ventilation effect meets the requirements. If necessary, repair and replacement measures can be taken to ensure that the ventilation effect is normal.

Environmental monitoring in the pharmaceutical industry is essential to ensure the quality and safety of drug production. Through real-time monitoring of parameters such as temperature, humidity, pressure and ventilation, potential problems can be detected and solved in time to ensure the stability of the production process and the controllability of quality. Pharmaceutical companies should establish appropriate monitoring requirements and control measures, and ensure the normal operation of the monitoring system and the accurate recording of data to ensure the safety and quality of the production environment.