LEL gas detector working principle

With the rapid development of industry, the issue of production safety is getting more and more attention. Combustible gas detection is one of the important means to ensure industrial safety, and LEL (Lower Explosive Limit) as an important combustible gas detection parameter, for the prevention and control of the production process of explosive accidents is of great significance. This paper will introduce the LEL gas detector working principle and its application in detail.

Introduction to the working principle of LEL

1.Definition of LEL

LEL, i.e. Lower Explosive Limit Concentration, refers to the lowest concentration of combustible gas in a mixture of combustible gas and air, under which an explosion can occur in the presence of an ignition source. Usually expressed as a percentage, e.g. LEL of methane is 5%.

2.Measuring principle of LEL

The measurement principle of LEL is mainly to detect the concentration of combustible gas in the mixture of combustible gas and air, so as to determine whether there is a risk of explosion. At present, the commonly used detection methods are catalytic combustion method, semiconductor sensor method and infrared absorption method.

LEL gas detector working principle

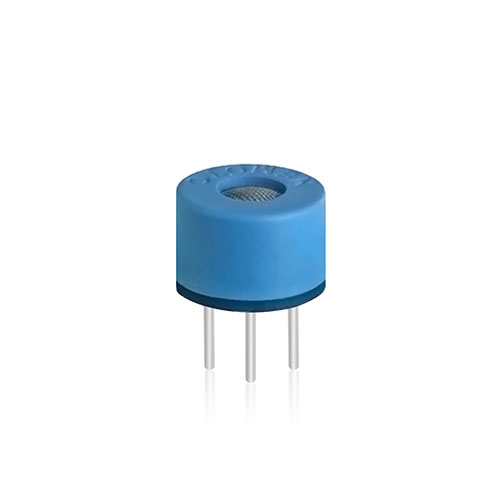

1.LEL gas detector structure

LEL gas detector detects combustible gases through the internal Combustible Sensor, which usually consists of a sensitive element, signal processing circuit and output interface, etc. The sensitive element is responsible for detecting combustible gases. The sensitive element is responsible for the detection of combustible gases and commonly includes platinum resistors, semiconductors and infrared absorbing materials. The signal processing circuitry converts the signal detected by the sensitive element into an electrical signal for display or control. The output interface is responsible for transmitting the signal to the back-end equipment, such as alarms, control systems and so on.

2.Sensor working principle

When the combustible gas enters the sensor, the sensitive element contacts the gas and undergoes chemical reaction or physical adsorption, which changes the resistance of the element. The signal processing circuit detects and processes the resistance change to get the electric signal related to the concentration of combustible gas. According to the size of the signal, it can be judged whether the concentration of combustible gas exceeds the LEL, so as to issue an alarm or take corresponding safety measures.

LEL Application Areas

1.Industrial Safety

LEL is most widely used in the field of industrial safety, petroleum, chemical, coal mine, natural gas and other industries need to monitor combustible gases to prevent explosions.

2.Environmental protection monitoring

LEL can also be used in the field of environmental protection, monitoring landfills, sewage treatment plants and other places that may produce combustible gases, to prevent fire or explosion caused by combustible gas leakage.

3.Other Fields

In addition to industrial safety and environmental protection monitoring, LEL technology is also widely used in aerospace, military, scientific research and other fields. For example, in the rocket fuel system, the concentration of fuel gas needs to be monitored in real time to ensure the safety of rocket launch.

Development trend of LEL technology

1.Technology Improvement

With the progress of science and technology, LEL sensors are expected to be further optimized in terms of sensitivity, stability, anti-interference ability, etc., to improve the accuracy and reliability of detection.

2.Expansion of new applications

As LEL technology continues to mature, its application in the smart home, Internet of Things and other fields will be expanded to provide more security for people’s daily life.