Methane leak detection

The Need for Methane Leak Detection

Methane is a component of natural gas and is used primarily as an industrial fuel source and as a chemical feedstock. It is usually harmless when stored properly, but the consequences of a leak can be severe. Methane is explosive in enclosed areas; liquefied methane floats on water and boils, and the resulting vapor cloud is flammable and produces toxic gases when it catches fire. The hazards to personnel working in the spill area should not be underestimated. High concentrations of methane can reduce the amount of oxygen breathed from the air, leading to mood changes, slurred speech, vision problems, nausea, vomiting, facial flushing, and headaches. In severe cases, breathing and heart rate changes, balance problems, numbness, and confusion may occur. Therefore, timely monitoring and warning of methane gas leaks is especially necessary.

What is used for Methane leak detection?

Methane leaks are usually detected using a methane leak detector, the current market commonly uses methane leak detector catalytic combustion methane detector technology and infrared methane detector technology principle.

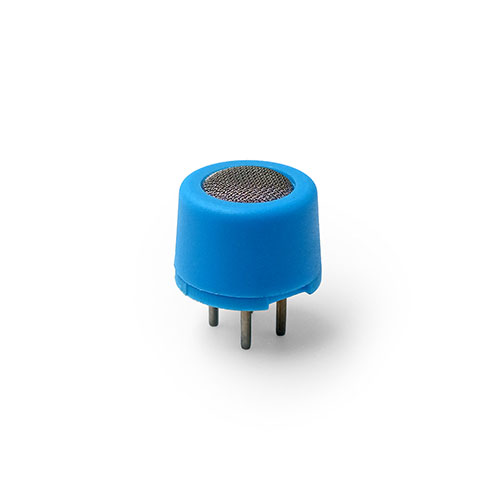

Catalytic combustion methane detector technology principle

Catalytic Combustion Methane Detector Technical Principle Workflow: It is the use of the Wheatstone bridge principle, by the detection element and the compensation element paired composition of the bridge arm, flameless combustion occurs on the surface of the sensitive body of the detection element when encountered with combustible gases, the temperature of the sensitive body increases, the resistance of the temperature-sensitive material increases, the output voltage of the bridge circuit becomes larger, the amount of the change in the voltage with the increase in the concentration of the gas increases into a positive proportion, according to the determination of the output signal size of the bridge can determine the detection of methane gas concentration. According to determine the size of the change in the bridge output signal can be determined to detect the concentration of methane gas.

Advantages: The catalytic combustion methane detector has the characteristics of good output signal linearity, reliable index, low price, and no cross-interference with other non-combustible gases.

Infrared methane detector technology principle

Infrared methane detector technology principle of workflow: the gas is to be measured continuously through a certain length and volume of the container, from the container can be translucent with two end faces in one of the end face of the sides into a beam of infrared light. When the infrared sensor wavelength and the measured gas absorption spectral lines coincide, infrared energy is absorbed, infrared light through the measured gas after the light intensity attenuation to meet the Lambert-Beer (Lambert-Beer) law, the greater the concentration of gas, the greater the attenuation of light. The greater the concentration of the gas, the greater the attenuation of light. At this time, the absorption of infrared light and the concentration of light-absorbing substances is directly proportional to the data, which can be measured through the measurement of gas attenuation of infrared light to measure the gas concentration.

Advantages: infrared methane detector is widely used, long service life (5 years life), high sensitivity, good stability, and non-toxic, less interference by the environment, not dependent on oxygen and other characteristics, methane detector has a high monitoring sensitivity, even if the micro-content of PPB or low concentration of PPM-level gas can be accurately distinguished. In addition, infrared methane detectors are generally compatible with analyzing high concentrations of 100% VOL methane gas.

About Methane Measurement Standards:

The standard value for methane detection is 5% VOL because methane in the air within 15.4% VOL by volume will explode when exposed to a spark. Therefore, the purity should be checked when igniting methane, and the mine should be well-ventilated. In addition, the maximum permissible concentration limit of methane in ambient air is <5%VOL, which means that the lower limit of the explosion of methane measurement is 5%VOL. Methane is basically non-toxic to human beings, but if the concentration of methane is too high, it will make the oxygen content of the air decrease significantly, and suffocate human beings. When methane is in the air up to 25% -30%, can cause headache, dizziness, fatigue, inattention, breathing, and heart rate, and ataxia. If not kept away in time, it can lead to death by asphyxiation.