NDIR sensors for industrial and environmental applications

With the increasing concern for environmental protection and industrial safety, NDIR (non-dispersive infrared) sensors play a key role as an important detection device in the field of environmental protection and industrial safety. In this article, we will discuss the principle, application cases, and future development prospects of NDIR gas sensors.

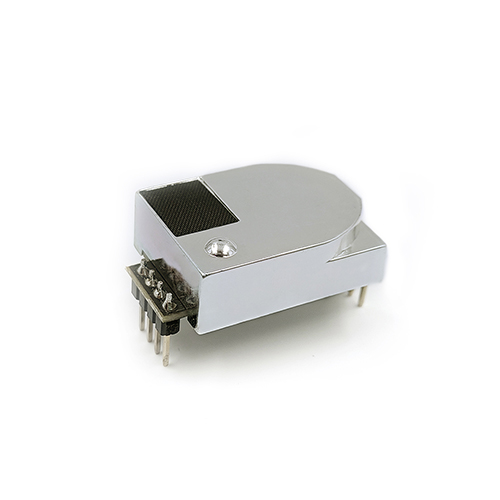

NDIR Sensor Working Principle

NDIR gas sensors use infrared spectral absorption properties to detect gas concentrations. The basic principle is to calculate the gas concentration by emitting a specific wavelength of infrared light into the sample and measuring the change in light intensity through the sample. When specific gas molecules are present in the sample, they absorb infrared light of a specific wavelength, resulting in a decrease in the intensity of light transmitted through the sample. By measuring the change in the intensity of the light, the NDIR sensor can determine the concentration level of the gas.

NDIR sensors in environmental protection

In environmental protection, NDIR gas sensors are widely used in air quality monitoring, air pollution control, and indoor air quality management. For example, in air quality monitoring, NDIR sensors can be used to detect the concentration of greenhouse gases such as carbon dioxide (CO2) and methane (CH4). This is critical for assessing air quality, understanding climate change, and developing relevant environmental policies. In addition, NDIR sensors can be used to detect harmful gases such as ozone (O3) and carbon monoxide (CO) to protect the public from air pollution.

NDIR sensors in the industry

In industry, NDIR gas sensors are also used in a wide range of applications. For example, in the petrochemical industry, NDIR sensors can be used to monitor the concentration of flammable gases such as ethylene (C2H4) and methane (CH4) to ensure the safety of the production process. In addition, NDIR sensors can be used to detect the concentration of toxic gases such as sulfur dioxide (SO2), ammonia (NH3), and chlorine (Cl2), as well as to monitor leaks of explosive gases such as hydrogen (H2) and propane (C3H8). By accurately detecting changes in the concentration of these gases in a timely manner, early warning and appropriate safety measures can be taken to maximize the protection of workers and equipment.

NDIR Sensor Development

With the continuous development and innovation of technology, the application of NDIR gas sensors in the field of environmental protection and industrial safety remains promising. On the one hand, the performance of sensors will be further enhanced, including improvements in sensitivity, accuracy, and response time to meet more demanding monitoring needs. On the other hand, the intelligence and interconnectivity of sensors will be enhanced, enabling them to interact with other devices and systems for data interaction and remote monitoring. This will help realize more efficient and convenient monitoring and management methods and drive continuous improvement in environmental protection and industrial safety.

NDIR sensors play an important role in environmental protection and industrial safety. By accurately and reliably detecting and monitoring gas concentrations, they help us to protect the environment, safeguard health, prevent accidents, and improve productivity. With further technological developments, NDIR gas sensors will play an even more critical role in the future, creating a cleaner and safer environment for us to live in.