Combustible gas leak detectors

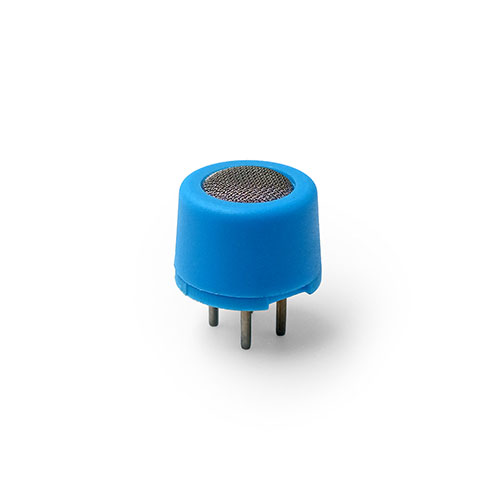

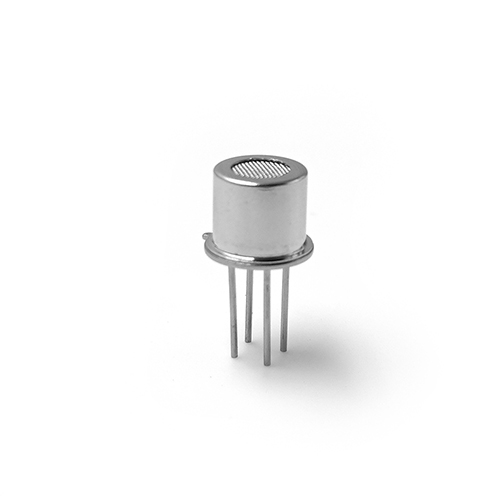

Combustible gas leak detectors are detectors that respond to single or multiple combustible gas concentrations. There are two types of combustible gas detectors: catalytic type and infrared optical type. Catalytic gas Sensor uses the resistance change of refractory metal platinum wire after heating to measure the concentration of combustible gas. When combustible gas enters the detector, it causes an oxidation reaction (flameless combustion) on the surface of the platinum wire. The heat generated increases the temperature of the platinum wire, and the resistivity of the platinum wire changes. The infrared optical type uses infrared sensors to detect alkane combustible gases in the on-site environment through the absorption principle of infrared light sources.

Introduction to Combustible gas leak detectors

Combustible gas leak detectors are industrial high-performance gas leak detectors that can be used to detect hydrocarbons (methane, ethane, propane, benzene, acetylene, butane, n-butane, isobutane, pentane, hexane, Gasoline, toluene, etc.), halogenated hydrocarbons (chloromethane, methylene chloride, trichloroethane, vinyl chloride), alcohols (methanol, ethanol, propanol), ethers (methyl ether), ketones (butanone, Acetone), methyl acetate and other compounds (hydrogen, sulfur dioxide, ammonia, hydrogen sulfide, industrial solvents, dry cleaning fluids, etc.). There are usually four classifications according to detection principles: thermal conductivity type, semiconductor type, catalytic combustion type (contact combustion) and infrared absorption type.

Combustible gas leak detectors are point-type gas detection equipment installed in explosive hazardous environments. They convert the combustible gas concentration on site into electrical signals and transmit them to the monitoring equipment located in the safe area to achieve the purpose of monitoring the combustible gas concentration on site. During the design and construction process, combustible gas detectors should comply with corresponding standards and requirements.

Where are Combustible gas leak detectors suitable for use?

Combustible gas leak detectors are suitable for various potential combustible gas leakage places, such as household gas use areas, industrial workshops, chemical laboratories, gas stations, etc. Installing combustible gas detectors in these places can detect dangers as soon as possible and take corresponding measures to prevent accidents.

How to choose Combustible gas leak detectors?

When purchasing Combustible gas leak detectors, you must first pay attention to their measurement range and accuracy. According to the needs of different places, select the appropriate measurement range and accuracy to ensure the accuracy of the test results. Secondly, you need to understand the sensitivity and response time of the detector. A detector with high sensitivity can detect flammable gas leaks earlier, and a detector with a short response time can alarm more quickly. Finally, factors such as the durability and explosion-proof performance of the detector must be considered.

How to install and use combustible gas detectors?

When installing and using combustible gas detectors, follow the instructions. Normally, detectors need to be installed in areas prone to flammable gas leaks, such as near gas pipelines and in poorly ventilated areas. The installation height of the detector must comply with standard requirements to ensure detection accuracy. When using it, check the working status of the detector regularly and replace the sensor and battery in time.