Industrial air quality sensor

In the industrial production process, whether it is the accumulation of gas generated by the reaction or the leakage of gas involved in production, it will cause certain threats and losses to the production operation. It is necessary to safely monitor the air in the space, and the industrial air quality sensor used to detect gases “came into being”.

As the core equipment of safety monitoring, industrial air quality sensor needs to have high sensitivity and perception of gas. Currently, common industrial air quality sensor technologies on the market include: catalytic combustion sensors, electrochemical sensors, semiconductor sensors, infrared photoion sensors and PID technology sensors.

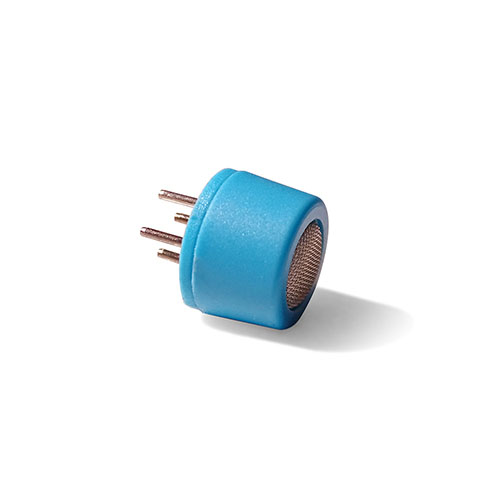

Catalytic combustion sensor

This type of sensor uses the Wheatstone bridge principle and consists of a detection element and a compensation element paired to form a bridge arm. When gas-sensitive materials (such as Pt electric heating wires, etc.) are energized, the flammable gas oxidizes and burns or oxidizes and burns under the action of a catalyst. The electric heating wire heats up due to combustion, causing its resistance value to change. The voltage change is positive as the gas concentration increases. proportion increases.

Advantages: The output signal has good linearity, reliable index, low price, and no cross-interference with other non-combustible gases.

Limitations: Only for monitoring flammable gases. Certain lead-containing compounds (especially tetraethyl lead), sulfur compounds, silicones, phosphorus compounds, hydrogen sulfide and halogenated hydrocarbons may poison or inhibit the sensor.

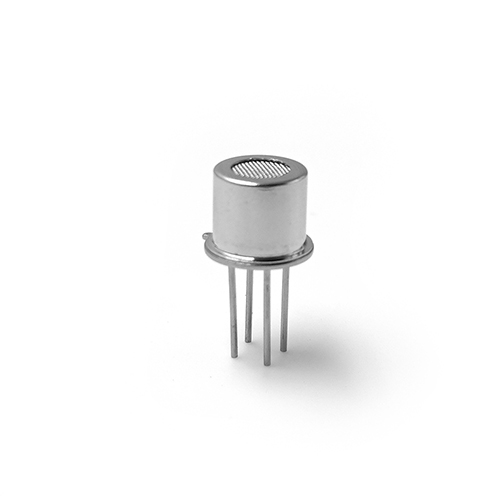

Semiconductor sensor

The working principle of this type of sensor is that after the surface of the metal oxide semiconductor adsorbs the target gas, its resistance changes. The gas concentration can be inferred based on changes in resistance threshold.

Advantages: Excellent sensitivity, can measure micro-leakage of gas.

Limitations: It is susceptible to interference from other gases, resulting in inaccurate detection and false alarms.

Electrochemical sensor

This type of sensor is mainly composed of a sensing electrode (working electrode) and a counter electrode. The working principle is to generate a relative electrical signal through the contact reaction between the sensing electrode and the gas being measured. The gas concentration is directly proportional to the electrical signal. Advantages: low power consumption, good repeatability, long life and high sensitivity. Currently, it is almost widely used in scientific research fields.

Limitations: The sensor requires approximately three weeks for stable operation, and extreme air humidity will shorten the sensor life. The longer the exposure, the shorter the lifespan.

Infrared sensor

This type of sensor operates on the Lambert-Beer law. It is to continuously pass the gas to be measured through a container of a certain length and volume, emit a beam of infrared light from one of the two light-transmissive end faces of the container, and then measure the radiation intensity of the infrared ray at the other end face. Finally, Based on the comparison of the absorption of infrared rays and the concentration of the light-absorbing material, the concentration of the measured gas can be known.

Advantages: It has good measurement specificity and mainly detects low-carbon chain hydrocarbons and CO2.

Limitations: The power consumption is relatively large, and the detection results are easily affected by dust and temperature.

PID sensor

This type of sensor is equipped with a high-energy ultraviolet chamber. When gas molecules absorb high-energy ultraviolet light and produce ionization, the current generated by the ionized particles is analyzed and amplified by software, and the molecule concentration can be inferred based on the size of the current.

Advantages: It can measure most VOC and TVOC gases, and the measurement accuracy can reach PPM level.

Limitations: high cost, small scope of application.

Fosensor Industrial air quality sensor is mainly used in the detection of combustible gases, toxic gases, oxygen, carbon dioxide and other gases in the industrial field. It can be directly used in Industrial Gas Detector. If you need it, please feel free to contact us.