Toxic gas detection sensors for power plants

With the advancement of science and technology, everyone has become quite familiar with electricity. Electricity plays an important role in our lives. The beacon in the dark and the neon light in the hustle and bustle are all wonderful experiences that electricity brings to us. However, during the power generation process, a lot of waste gas is inevitably produced, which also has adverse effects on our environment and physical health.

There are many types of common power plants, such as thermal power plants, hydroelectric power plants, atomic power plants, geothermal power plants, wind power plants, tidal power plants and solar power plants. Since these power plants use different power sources, the amount of exhaust gas they emit and the pollutants in the exhaust gas are also different. Among them, hydraulic, atomic energy, geothermal, wind, tidal and solar power plants use relatively clean energy, so they have a relatively small impact on the atmospheric environment; while thermal power plants mostly use coal-fired boilers, and their exhaust gases are The amount is large, the smoke composition is complex, and it causes serious pollution to the atmosphere. Flue gas from coal-fired boilers in thermal power plants is the main source of pollution in the power industry.

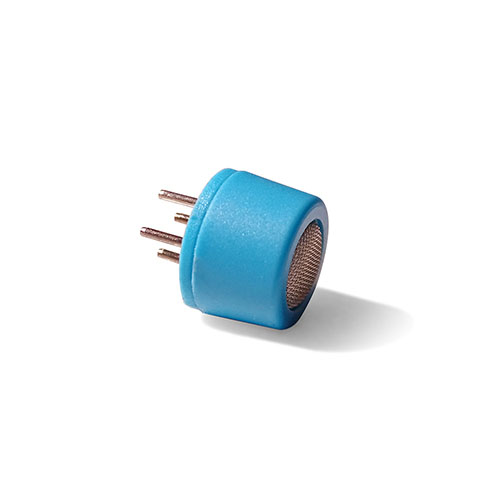

A variety of dangerous gases will be produced during the power production process. These gases are very harmful, ranging from poisoning to explosion, causing serious losses to the country and people’s lives. In order to avoid and reduce losses, Toxic gas detection sensors must be used to monitor flammable and toxic gases generated in the power system. So what gases need to be monitored in power plants? Fosensor will introduce it to you below, let’s take a look.

In power systems, common gases that need to be monitored include: oxygen, carbon monoxide, hydrogen sulfide, sulfur dioxide, combustible gas, ammonia, sulfur hexafluoride, hydrogen, nitrogen oxides, etc.

(1) Toxic and harmful gases (such as carbon monoxide, hydrogen sulfide, etc.) and oxygen. In the process of power production, there are many places with limited space, such as cable tunnels, communication cable tube wells, sewage treatment wells, heating channels, etc. These spaces are relatively closed and prone to produce toxic and harmful gases. At the same time, they are places where workers often enter. Toxic and harmful gases must be detected before entry to prevent poisoning. Moreover, due to the lack of air circulation in these places, it is easy to cause hypoxia, so an oxygen sensor must be used to detect oxygen.

There are two main reasons for the lack of oxygen in limited spaces: first, oxygen consumption caused by biological respiration or material oxidation; second, simple asphyxiating gases such as carbon dioxide, nitrogen, and methane occupy oxygen in limited spaces. The safe oxygen concentration for personnel is between 19.5%vol and 23.5%vol. Lower than 19.5%vol or higher than 23.5% may cause harm to the human body.

(2) Sulfur dioxide, nitrogen oxides. There are a large amount of incompletely treated sulfur dioxide and nitrogen oxides in the products of desulfurization and denitrification projects of coal-fired units in the power industry. In order to prevent air pollution, it is necessary to detect their content. When the standards are exceeded, adjust the process and ingredients to reduce sulfur dioxide and nitrogen oxides. the production of things.

(3) Combustible gas. Gas is the main fuel energy used in many places now. Gas is used as fuel in the boiler rooms and heating rooms of power plants. In addition, there are combustible gases in generating units, gas pressure regulating stations, and gas tank areas. Combustible Sensors must be used to detect leaks of combustible gases in these places to eliminate these potential sources of danger. In addition, power plants have their own fuel storage areas, where combustible gases are also generated, and leaks of combustible gases must also be detected.

(4) Ammonia gas. There are a large number of water supply pipes in power plants, and the water supply system is prone to corrosion over a long period of time. Therefore, when adding water to the boiler, it is necessary to add ammonia to adjust the pH of the water, and add oxygen scavengers for chemical deoxidation to prevent the water supply system from being corroded. Ammonia is also used as a reducing agent in the desulfurization and denitrification processes of power plants. Therefore, there are ammonia production sites and ammonia storage areas in power plants. Since ammonia is extremely dangerous and leakage can cause poisoning and explosions, it must be treated It is tested.

(5) Sulfur hexafluoride. Sulfur hexafluoride has good insulation properties, stable physical and chemical properties and excellent arc extinguishing properties. It is widely used in high-voltage equipment, such as: high-voltage switches, high-voltage transformers, closed combination capacitors, high-voltage transmission lines, etc. It is most commonly used in high-voltage transformers in power plants, but sulfur hexafluoride is one of the six greenhouse gases currently discovered. At least half of the sulfur hexafluoride gas produced globally every year is used in the power industry, and it is still used in the power industry. It is constantly growing, and the growth rate is alarming. It needs to be strictly tested to prevent leakage and air pollution.

(6) Hydrogen. Since hydrogen has good heat transfer and heat dissipation properties, hydrogen-cooled generator sets take advantage of this characteristic of hydrogen. The generator uses hydrogen as a cooling medium. Hydrogen leakage needs to be detected at the generator and hydrogen production station.